CMA Terminals Khalifa Port: State-of-the-art energy and data transmission with VAHLE TriMotion Compact

TriMotion Compact

The VAHLE fact check

Industry

20 RTG Cranes

16 Lanes

Commissioning 12-2024

Total system over 5,700 meters

The background

Khalifa Port in Abu Dhabi is one of the most modern deep-sea ports in the world and, with a water depth of 18.5 meters, plays a central role in international container traffic. As a strategic transshipment point, it connects over 25 leading shipping companies with more than 70 global destinations. With the expansion of the terminal by CMA Terminals Khalifa Port - a joint venture between CMA TERMINALS and the AD Ports Group - the operator is pursuing the goal of significantly increasing handling capacities and at the same time implementing state-of-the-art automation technologies that also contribute to the implementation of the CMA CGM Group 's global sustainability strategy.

The challenge

CMA Terminals Khalifa Port was looking for a solution that would work reliably at all times, even under the extreme climatic conditions of the region - heat, sand, dust and high humidity. The requirement was for a robust, low-maintenance and at the same time highly efficient system for energy and secure data transmission that would guarantee the reliable supply and automation of the RTG cranes in the terminal at all times. There was also a tight schedule: The installation had to be completed within a tight timeframe, as the terminal was officially due to go into operation at the end of 2024.

Our solution

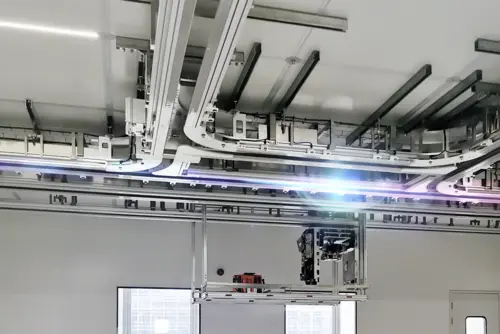

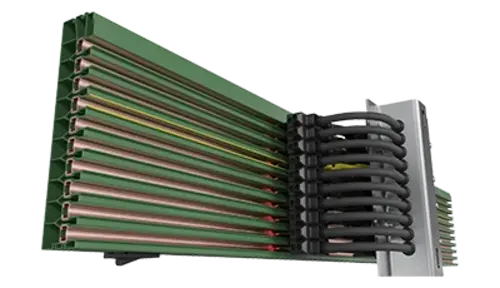

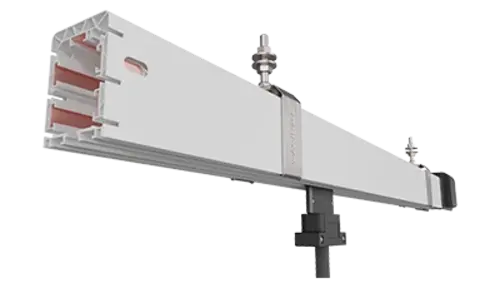

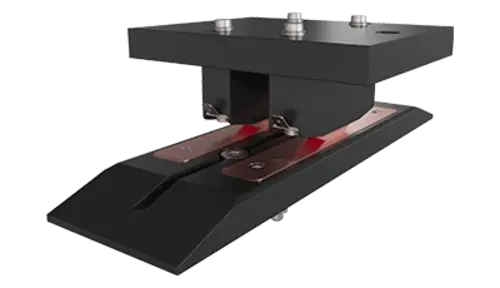

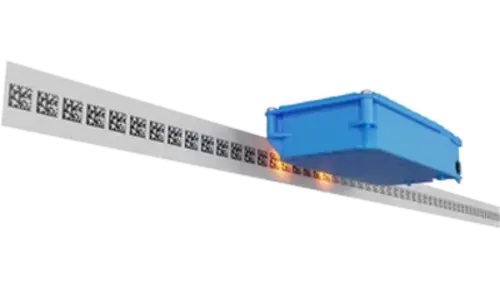

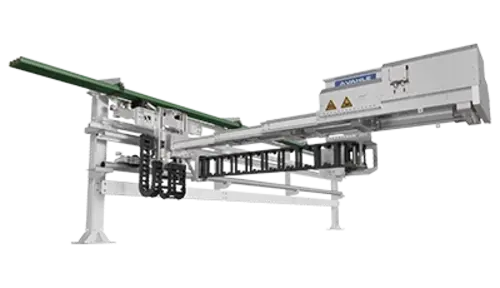

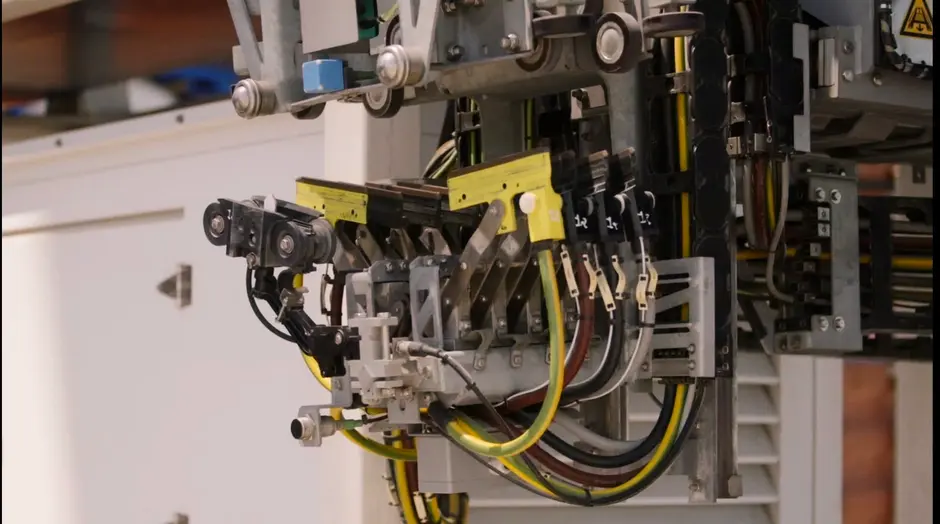

The VAHLE TriMotion Compact system was used for the electrification and remote control-ready equipment of the 20 RTG cranes in the new terminal section - consisting of the system bundle of the U35 conductor system and the fail-safe SMGX data communication.

A total of 16 aisles with a respective length of 355 meters were implemented - this corresponds to a total system length of around 5,700 meters. Thanks to the compact design and standardized execution of the TriMotion Compact system, the implementation could be carried out efficiently even within the tight project timeframe.

The complete system was installed on schedule and successfully put into operation at the end of November 2024. This ensures a reliable energy supply and data communication for automated RTG operation in the long term.

By switching to a fully electrified solution with TriMotion Compact, the terminal is also making an active contribution to reducing emissions - a further step towards sustainable port operations. VAHLE makes it possible.

Your Vision. Our Solution.

The facts

- 16 lanes, each 355 m long

- Total system length: 5,700 m

- Number: 20 RTG cranes equipped

- System: Energy and data transmission via TriMotion Compact System (U35 conductor rail + SMGX data communication)

- Project period: June 2024 to November 2024 (installation and commissioning)

- Customer: CMA Terminals Khalifa Ports

Would you like to see the system live in action?

Click here for the reference video on YouTube!