New pickup - Large amount of energy with small size

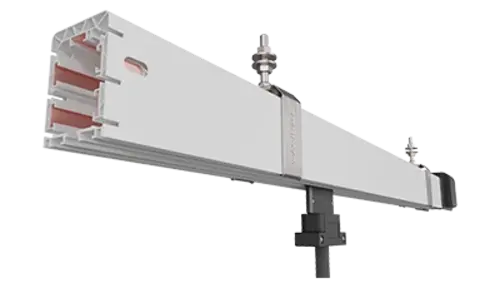

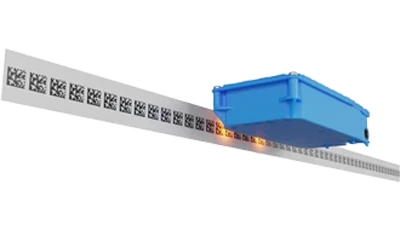

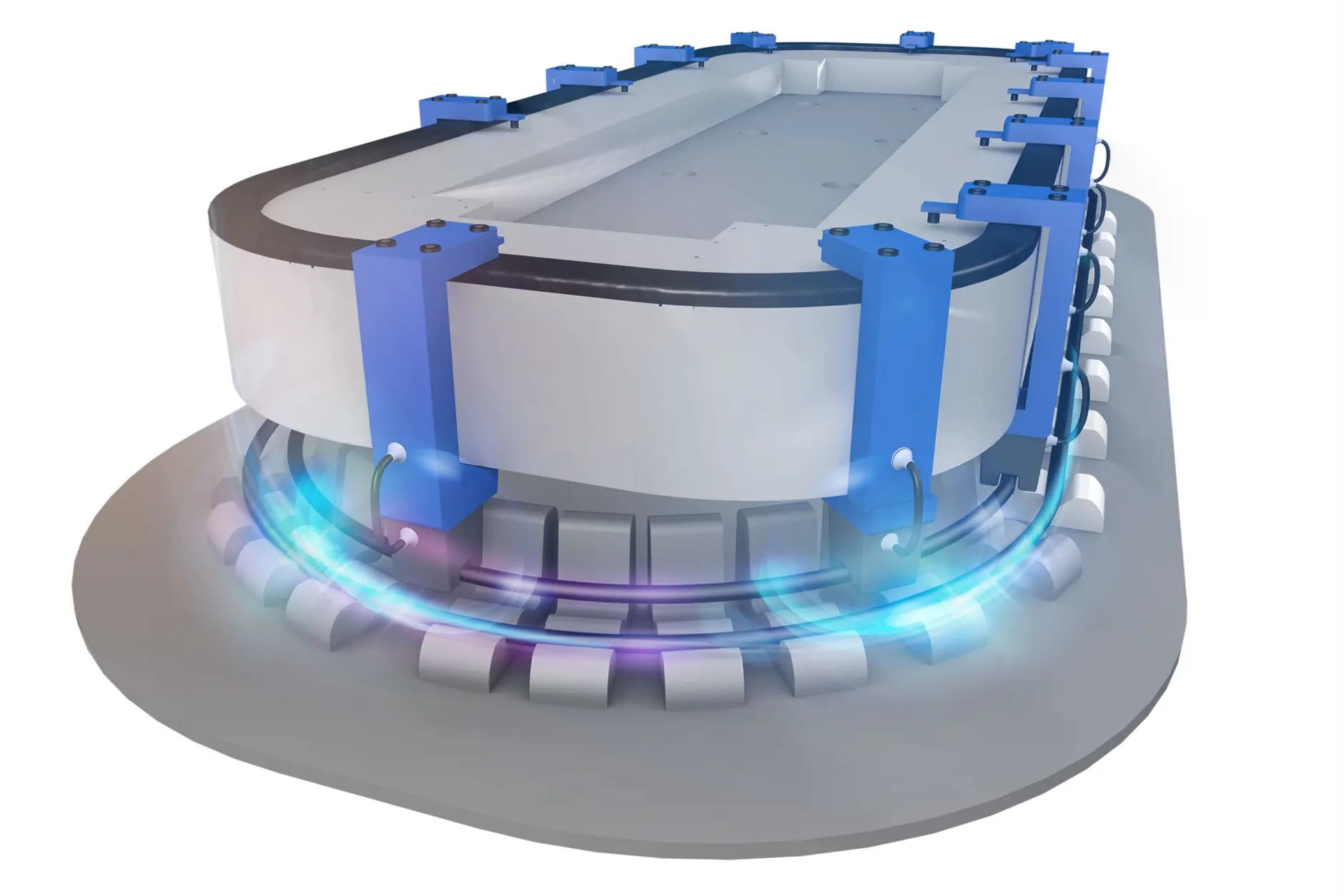

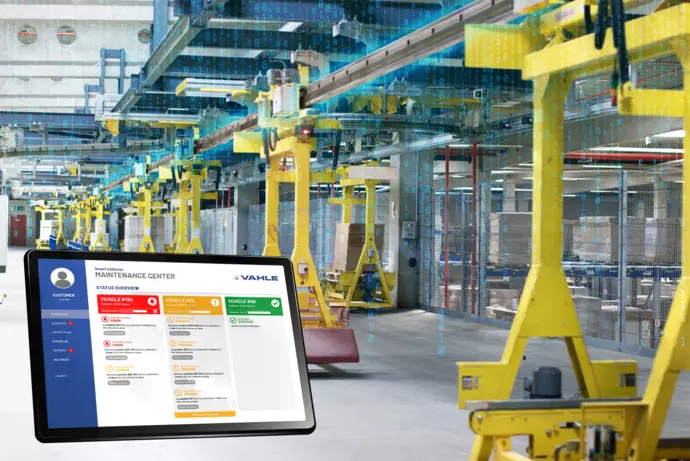

Product innovation: Paul Vahle GmbH & Co. KG has presented an innovative solution for contactless power transmission for the packaging machine industry: the vPOWER U015 Pickup. The system makes it possible to continuously supply the moving elements, also called movers, of packaging machines with electrical energy inductively.

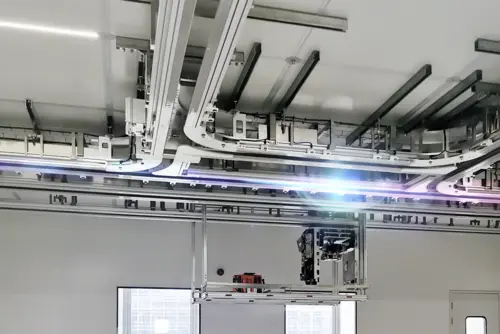

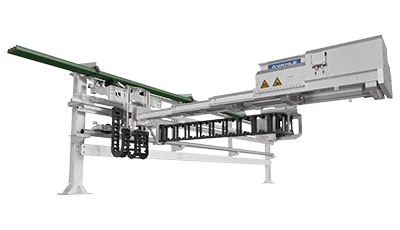

In this way, customer applications can achieve higher process outputs than if the power had to be transmitted via complex alternative solutions. The vPOWER U015 pickup is a standard solution that can be integrated into various machines. The first systems have been implemented with the so-called iTRAK from the US company Rockwell Automation, Inc. Other well-known companies are also already interested in the VAHLE solution.

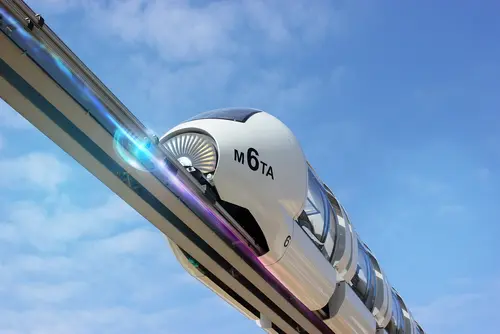

"With the vPOWER U015 Pickup, we enable the packaging industry to greatly increase its production output. Moreover, the complexity of the energy supply can be reduced and the robustness increased," says Marc Detweiler, product manager at Paul Vahle GmbH & Co. KG. Contactless power transmission allows the movers installed in the machines to reach maximum speeds that cannot be achieved with conventional power transmission systems. With classic transmission methods such as the conductor rail, strong friction occurs between carbon and copper at high speeds. This can cause wear on the power supply or, in sensitive sectors such as the food industry, damage to the products being packaged. Point inductive charging also reduces the production volume, as it can only be carried out when the system is at a standstill.

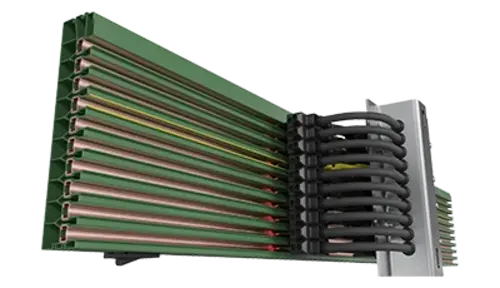

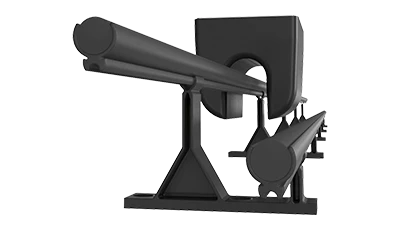

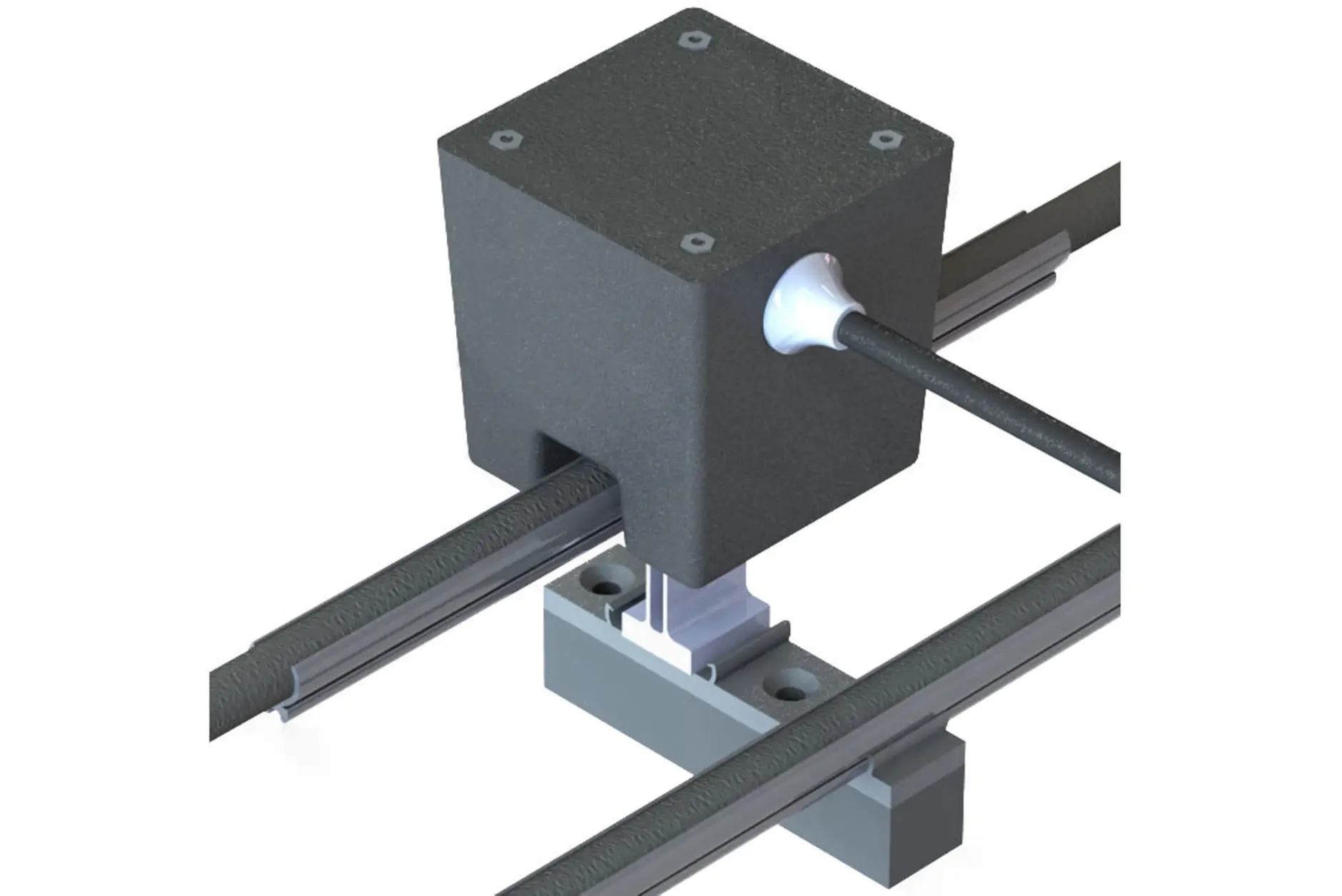

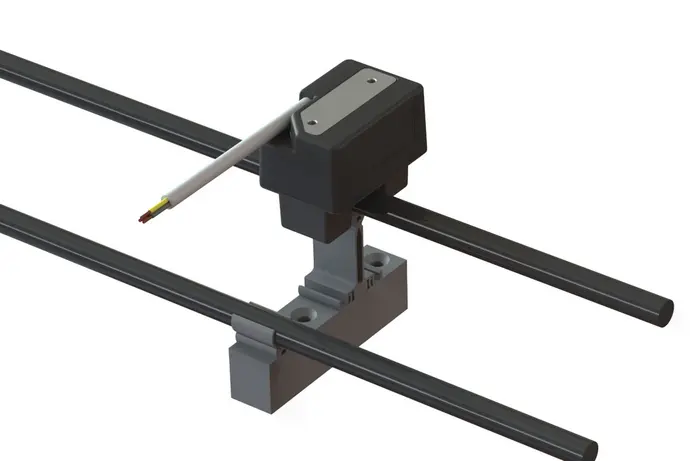

The new VAHLE Pickup works like a transformer: the primary winding consists of a power line wrapped around the packaging machine. It generates a permanent 45 A high-frequency current. The secondary winding is located on the mobile pickup and absorbs the energy inductively. There is no risk of wear on the cable, nor are there any open contacts that could cause interference from dirt or water.

The maximum power of the new VAHLE pickup is 150W and a voltage of 24VDC. At the same time, the vPOWER U015 pickup is only 67.4 x 67.4 x 71 mm and weighs only 650 g. "VAHLE is the first supplier to deliver a system for inductive transmission of such an amount of energy in this small size and with this low weight," Detweiler says.

VAHLE has so far installed the system in four test installations at customers in the packaging machinery sector. Among them is the iTRAK from Rockwell Automation, Inc. Michaela R. Kaufmann, global product manager for Rockwell Automation, Inc.'s iTRAK systems, describes the solution as a perfect match. "The new VAHLE pickup expands the unlimited flexibility of our technology by adding power to individual movers." In principle, the vPOWER U015 pickup is suitable for almost all systems as long as good mechanical guidance is available.

Related files