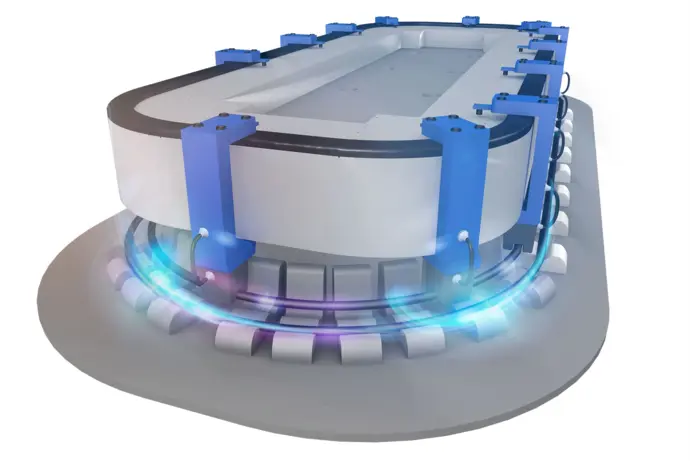

Contactless energy transmission

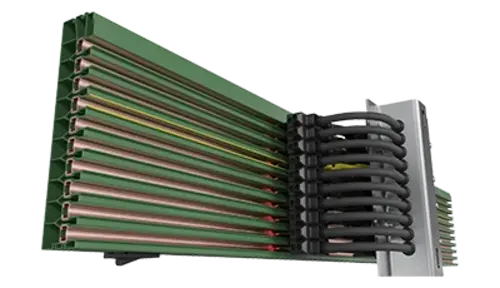

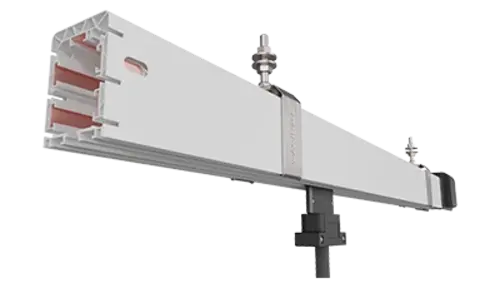

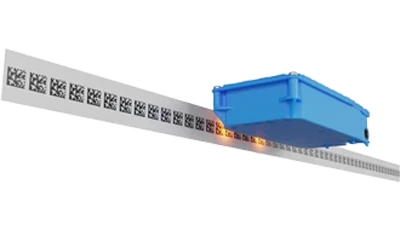

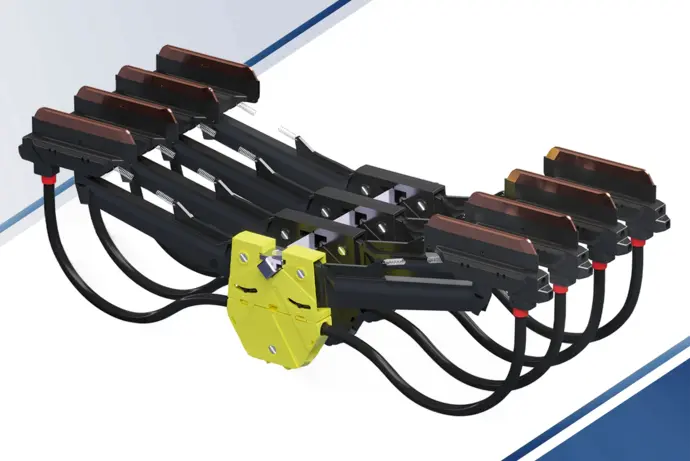

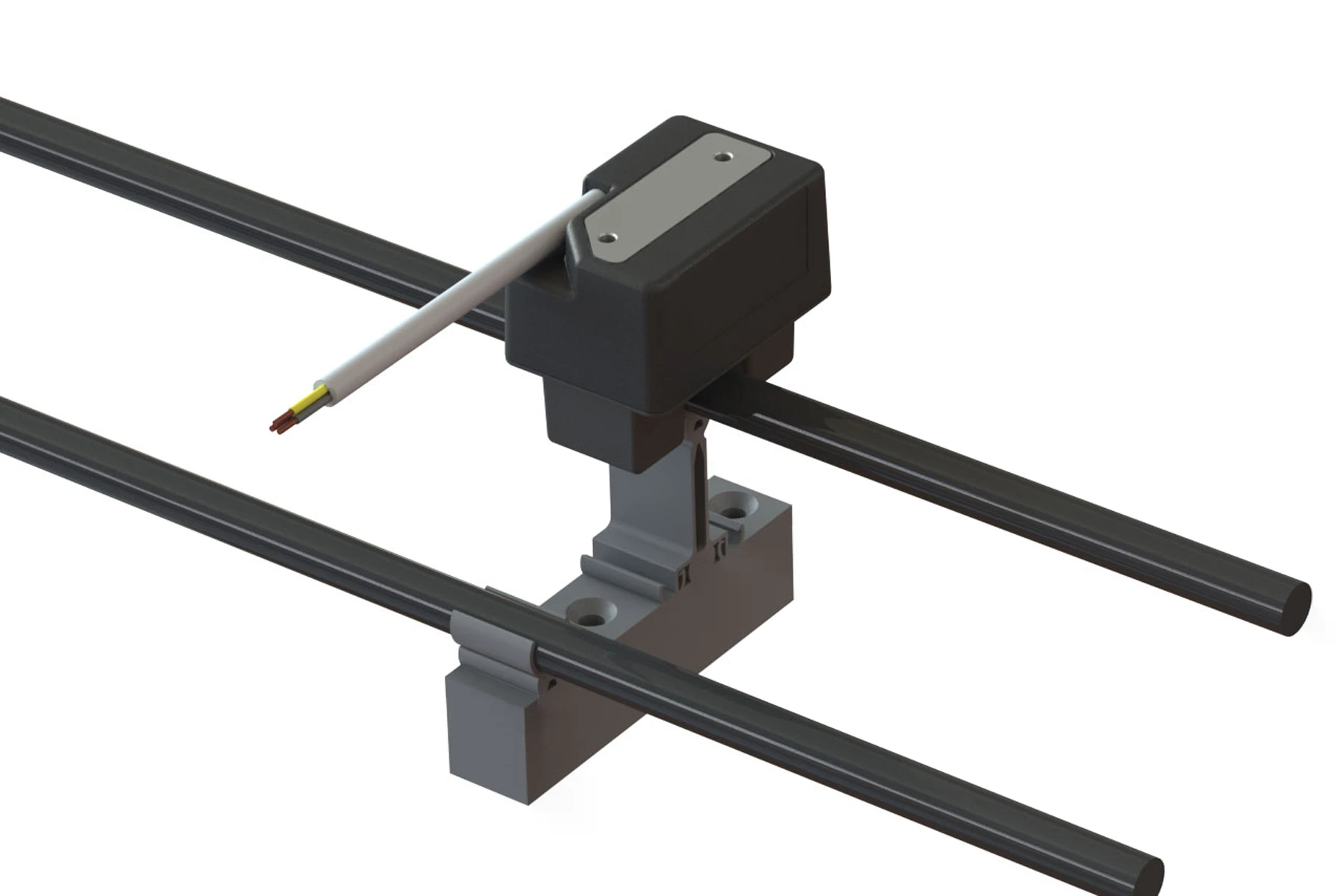

With the vPOWER U007, VAHLE is launching a new pickup on the market. The inductive current collector convinces with its low weight of only 175 grams, which optimizes the maximum possible payload of the movers. Its short dimensions make it the most compact product on the market.

The innovative solution delivers a peak power of 70 watts at 24 volts DC. It is primarily designed for use in modern packaging and production machines and supplies the applications on the movers with power at high speeds. Thanks to a flexible cable outlet that can be freely configured in terms of length, the IP67-rated pickup can be used universally. It is also short-circuit-proof, temperature-monitored and has current and voltage limiting.

"It currently doesn't get any more compact than this. With the new vPOWER U007 pickup, we realize contactless power transmission in an absolutely small installation space," says Johannes Schipflinger, product manager at Paul Vahle GmbH & Co. KG. At the beginning of the new year, the Kamen-based system provider for mobile industrial applications is introducing its latest inductive current collector and launching it internationally. Schipflinger: "There are currently no comparable products on the market."

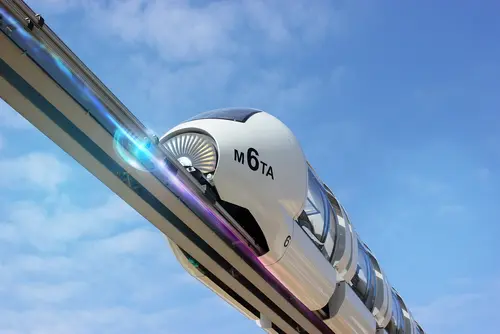

The vPOWER U007, which is particularly lightweight at just 175 grams, enables a maximum payload for the individual movers and delivers 70 watts of power with a regulated output voltage of a constant 24 volts at the DC level. "The product is designed for speeds up to 6 meters per second and 5g acceleration on the drive side. These requirements cannot be met with conventional contacting conductor systems," explains the expert.

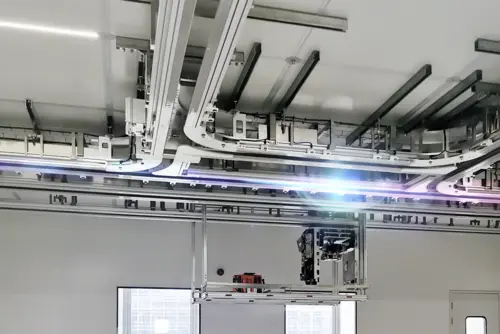

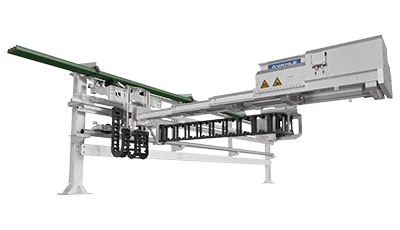

Primary target groups for the pickup are manufacturers of linear motors and the system integrators of modern packaging and production machines. "The energy we supply powers the actuators and sensors on the guided carrier vehicles. These can be grippers, vacuum pumps, control elements or encoders," says Schipflinger. This means that electrical energy can now be transmitted very conveniently without contact, which previously required a great deal of engineering effort. Ultimately, he says, the pickup can be used wherever energy is transferred to mobile applications and the necessary precise mechanical guidance is available: "By using the powerful U007, production efficiency and flexibility can be increased."

Thanks to its small dimensions of 40 millimeters in length, 48 millimeters in height and 60 millimeters in width, as well as a flexible cable outlet, the inductive current collector can be integrated into almost any system. "Short-circuit protection, overcurrent and overvoltage limitation, and a thermal shutdown also make it particularly safe to use," says Schipflinger.

The new and powerful product is available now and worldwide.

Click here for the U007 data sheet.