VAHLE is an associated partner in the DC-INDUSTRIE2 funding project

"Direct current for the factory of the future" - with this guiding principle, the research project "DC-INDUSTRIE2" was launched on October 1, 2019, in which the potential of direct current technology for industrial production facilities is to be investigated. DC-INDUSTRIE2 follows directly on from the very successful DC-INDUSTRIE research project, which focused on the development, adaptation and testing of power electronic devices for supplying and protecting DC networks in production cells, as well as methods for their robust operational management. In Phase 2, the DC grid will be expanded into an intelligent DC grid for a production hall or large-scale process plant.

"DC technology has many advantages that can be used to meet the requirements of a modern, intelligent industrial power grid. For example, new energy generation systems such as photovoltaics or energy storage systems can be integrated very easily, since they generate a DC voltage anyway. Furthermore, plant availability increases because a DC grid can react flexibly to disturbances in the upstream AC supply grid. "A DC grid can even actively support the AC grid; this grid serviceability is particularly important in weak grids or with a high proportion of decentralized energy producers such as photovoltaics," reports Prof. Dr. Holger Borcherding (TH OWL), the scientific director of DC-INDUSTRIE2.

In terms of content, the project builds on the results of DC-INDUSTRIE. Here, a comprehensive system concept has already been developed that will now be expanded for larger plants. "Openness and simplicity are particularly important to us. This was also the key to success in the previous project. We want everyone to benefit from the results," says Dr. Hartwig Stammberger (Eaton Industries GmbH) as overall project manager. With 35 industrial partners, 5 research institutes and the ZVEI (German Electrical and Electronic Manufacturers' Association), which supports the project with an industry working group as part of its association activities, DC-INDUSTRIE2 is one of the largest collaborative research projects in Germany. The consortium would particularly like to thank the German Federal Ministry for Economic Affairs and Energy, which is funding DC-INDUSTRIE2 as part of the 7th Energy Research Program under grant numbers 03EI6002A-Q, as well as Project Management Jülich for providing content and administrative support to the 18 funded partners.

The 13 industrial partners BLOCK, BMW, Daimler, Eaton, E-T-A, HOMAG, KEB Automation, LAPP, Lenze, LTI Motion, Phoenix Contact, SMA Solar Technology, Weidmüller together with the 5 research institutes Technische Hochschule Ostwestfalen-Lippe, Technische Universität Braunschweig, Fraunhofer IPA, Fraunhofer IISB, University of Stuttgart and the 22 associated partners ABB, AMK, Audi, Bauer Gear Motor, Bender, Danfoss, Dehn, ESR Pollmeier, Gerotor, Harting, JEAN MÜLLER, KUKA Deutschland, KUKA Systems, LEONI Kabel, LEONI Special Cables, Maschinenfabrik Reinhausen, Paul Vahle, Puls, Rittal, SEW-PowerSystems, Siemens and Wöhner are researching the industrial DC grid of the future.

For more information on industrial DC grids, visit www.dc-industrie.de.

The VAHLE Group is an associated partner in the DC-INDUSTRIE2 funding project and is specifying products for a technology change and its future emerging market requirements.

The system solutions are developed in the company's own research department to meet the relevant DC requirements and are subject to strict test procedures.

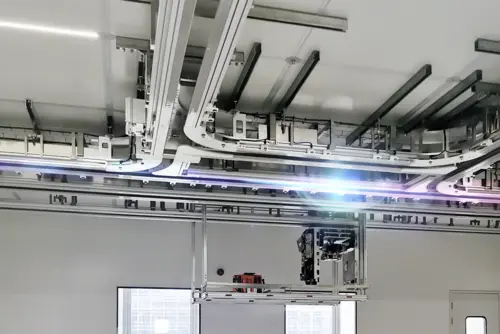

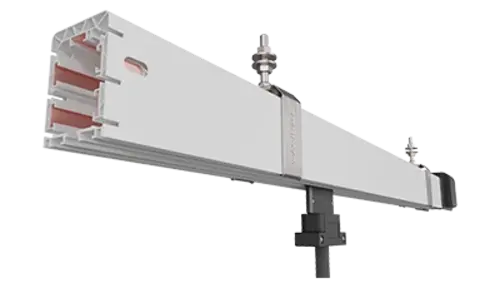

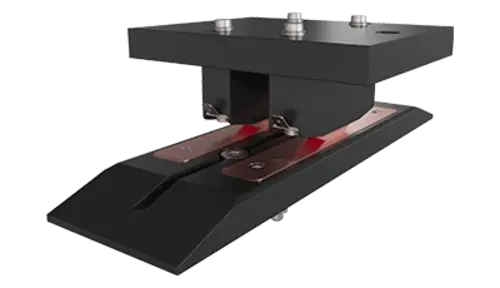

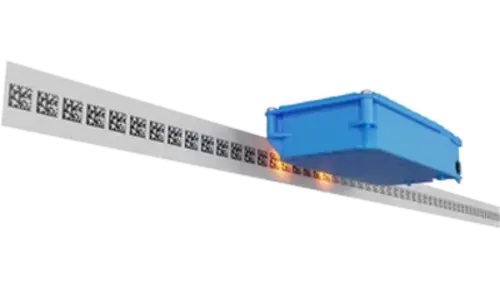

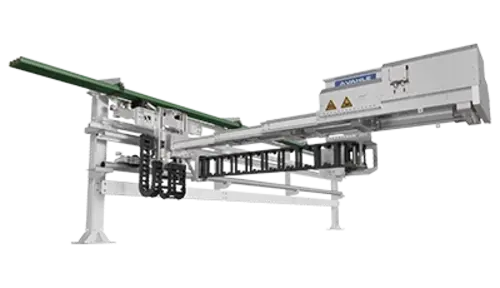

In addition, VAHLE will equip a test facility at a well-known automotive manufacturer with the single-insulated U10 conductor system as well as the SMGM data transmission system. Special attention will be paid to the future monitoring and measuring technology in our conductor rail systems. We are looking forward to cooperating with the partners in this future-oriented project. At the same time, VAHLE is consortium leader in the EU-funded project effiDCent.

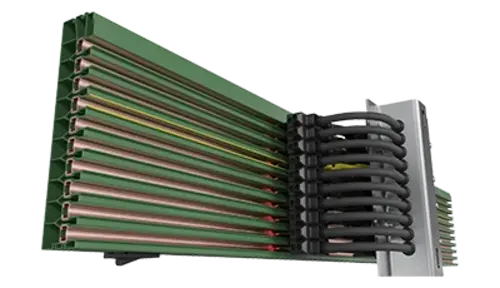

In the effiDCent funding project, Paul Vahle GmbH & Co KG, together with consortium partners from research and industry, is researching a DC-fed conductor system with integrated intelligent energy storage, central DC feed, buffer capacitors and arc monitoring, which is intended to optimize energy transmission in production lines in the manufacturing industry.