Construction of the VAHLE Campus is progressing: Köster GmbH, Fehr and Stöcklin Logistik won as partners

VAHLE Campus: Köster assumes overall project responsibility as general contractor. The automated warehouse solutions are supplied by Fehr and Stöcklin Logistik. VAHLE is investing a total of around 60 million euros in ultra-modern work, production and logistics areas.

Paul Vahle GmbH & Co KG's largest investment project is increasingly taking shape: With the awarding of central construction and logistics trades to renowned partners - Köster GmbH as general contractor, Fehr Lagerlogistik AG for the automated honeycomb warehouse, Stöcklin Logistik GmbH for small parts and pallet warehouses and the architectural firm Dälken - the new building at the headquarters in Kamen is entering the next phase.

"The awarding of these central trades is a decisive milestone for the construction of our VAHLE Campus," says Achim Dries, Managing Director of Paul Vahle GmbH & Co. KG, adding: "We are delighted to be working with experienced and renowned partners who have understood our project from the outset and have developed it further with great expertise."

The general contractor Köster: "Radiance for the region"

As the general contractor, Köster GmbH from Osnabrück is responsible for the overall structural realisation of the VAHLE Campus. The company is assuming overall responsibility for the project - from the four-storey administration building and modern production and logistics halls to the entire campus concept. Köster not only has decades of experience in industrial and commercial construction, but also extensive regional expertise: successful projects such as the Remondis expansion in Lünen or the Woolworth headquarters in Unna underline the reliability and effectiveness of the project team. "We are proud to be able to realise a project of this magnitude together with VAHLE," explains Björn Bongartz, Managing Director Building Construction West at Köster GmbH. "The VAHLE Campus is a real project for the future that is not only architecturally impressive, but will also have an economic and technological impact on the entire region."

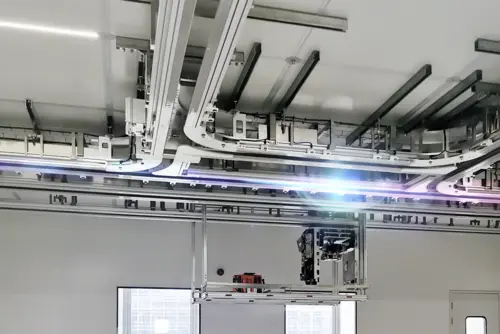

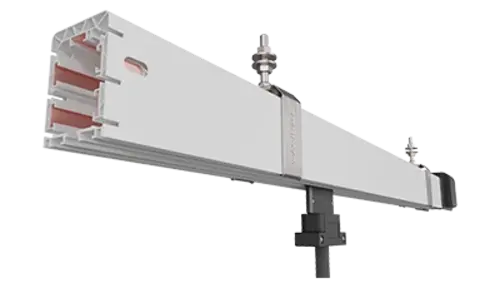

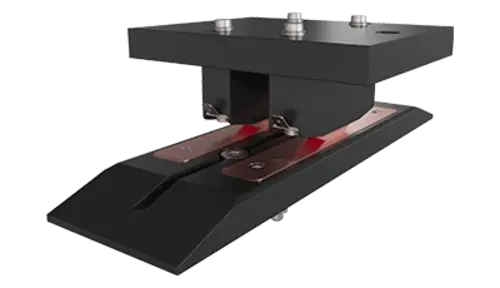

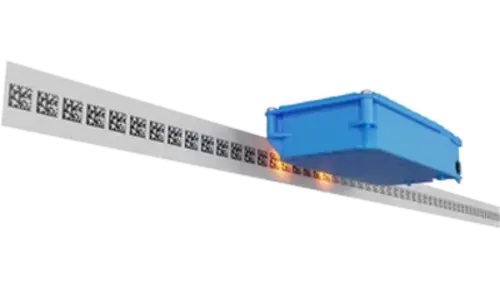

Automated honeycomb warehouse from Fehr

VAHLE is relying on Swiss intralogistics experts Fehr for the intralogistics infrastructure. The centrepiece is an automated honeycomb warehouse that is directly connected to production, packaging and dispatch. With a length of 80 metres, a width of 21 metres and a height of 17.5 metres, the system offers space for 2,500 storage cassettes. Two storage and retrieval machines, two longitudinal conveyors, a carousel and a total of 17 access points and 15 transport trolleys will ensure highly efficient material flows in future.

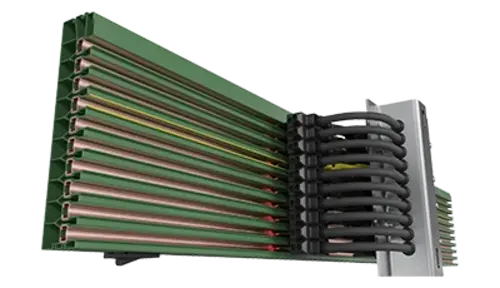

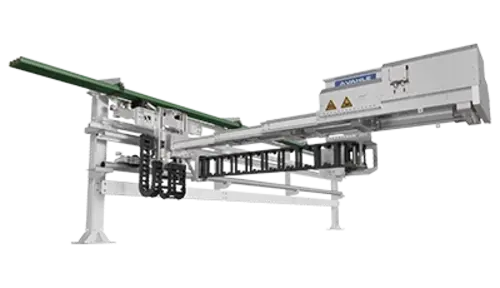

Automated small parts and pallet storage over two floors

Stöcklin Logistik complements the VAHLE Campus with innovative storage systems. An automated small parts warehouse (AKL) with over 41,500 storage locations and an automated pallet warehouse (APL) with 1,900 storage locations will be realised - each over two floors. The focus is not only on efficiency and capacity, but also on ergonomics, ease of use and sustainable, economical operation.

Architectural concept with a focus on sustainability

The architects at Dälken GmbH emphasised a clear design language and the use of sustainable materials in the overall architectural concept of the campus. The design is characterised by openness, high functionality and compliance with strict ecological standards. Plans include the integration of photovoltaic systems and heat pumps, which will make the campus an energy-sustainable location.

Pioneering future project for the region

With a total investment of over 60 million euros, VAHLE is making a clear commitment to the Kamen site and the region. On a floor space of around 15,300 square metres, ultra-modern working environments, production facilities and logistics areas are being created that will set new standards in the industry. "For us, Kamen is much more than just a location - it is the heart of our company history, the root of our success and a central component of our vision for the future," says Dries, adding: "Together with our partners, we are convinced that we will create a working and innovation environment by 2027 that will sustainably strengthen VAHLE, our employees and the entire region."

The VAHLE Campus is scheduled to open in the second half of 2027. Interested parties can find more information about the project and the company on theVAHLE Campus project page.

Facts about the VAHLE Campus

Project partner

|

Further information about Köster GmbH can be found atkoester-bau.de

Further information about Fehr can be found atfehr.net

You can find more information about Stöcklin Logistik atstoecklin.com

You can find more information about Dälken atdaelken.de