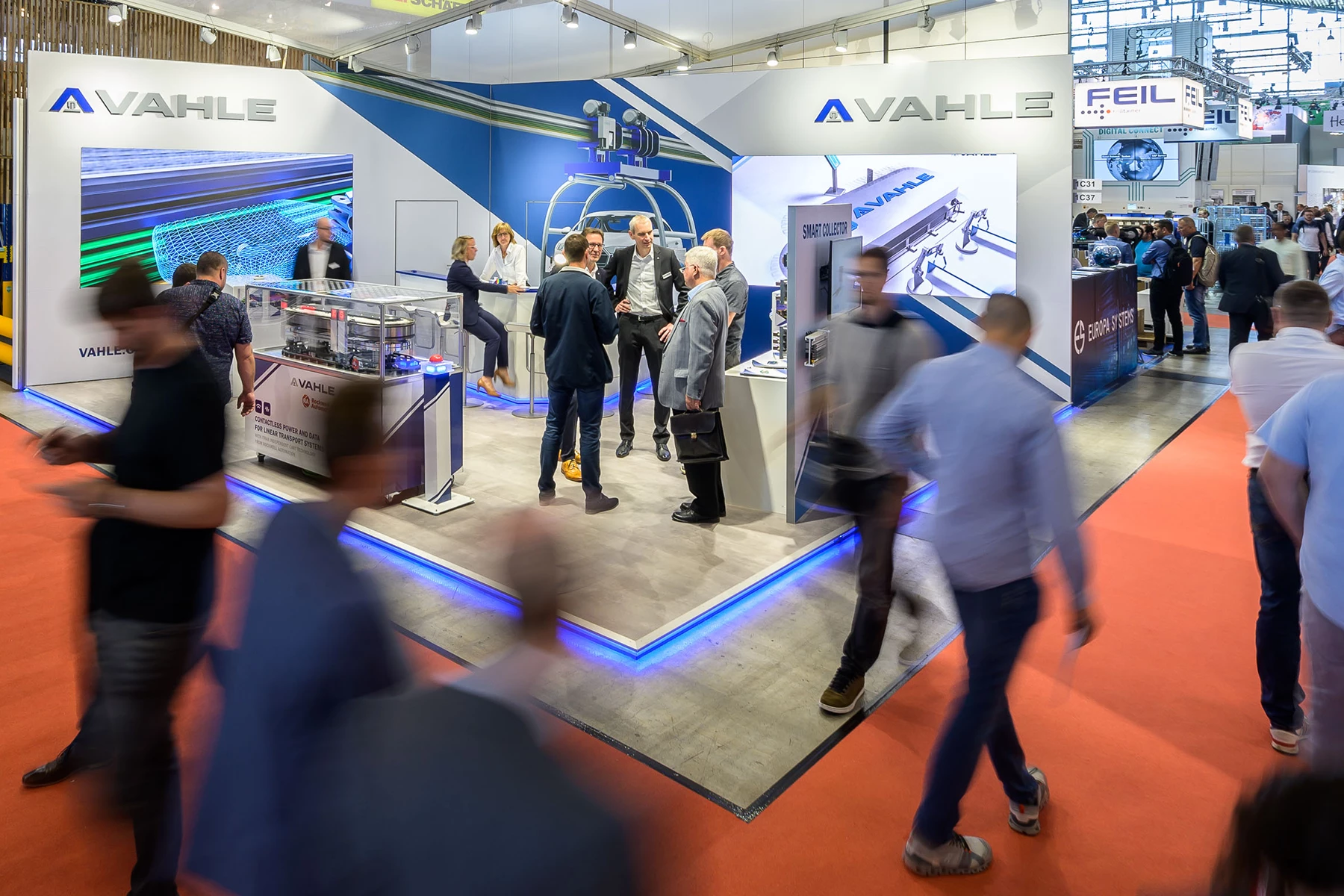

SPS: VAHLE shows innovations for automatic systems

With several innovations, Paul Vahle GmbH & Co. KG will be exhibiting at this year's SPS. For the first time at the trade fair, which will take place from November 8 to 10 in Nuremberg, the globally unique intelligent current collector system Smart Collector will be on display. Other highlights at the VAHLE booth in Hall 4, Booth 336 include the modular compact conductor line VCL and the latest control generations. In addition, the Rockwell Automation iTRAK, which is equipped with inductive VAHLE systems for non-contact power transmission, will be presented.

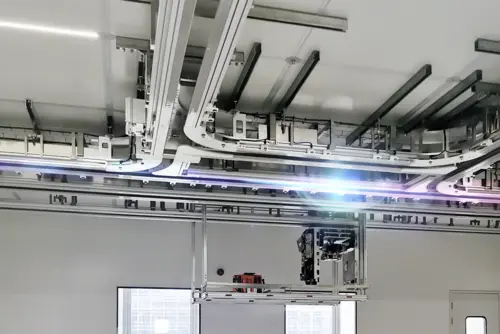

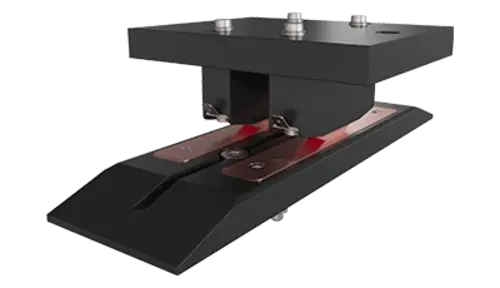

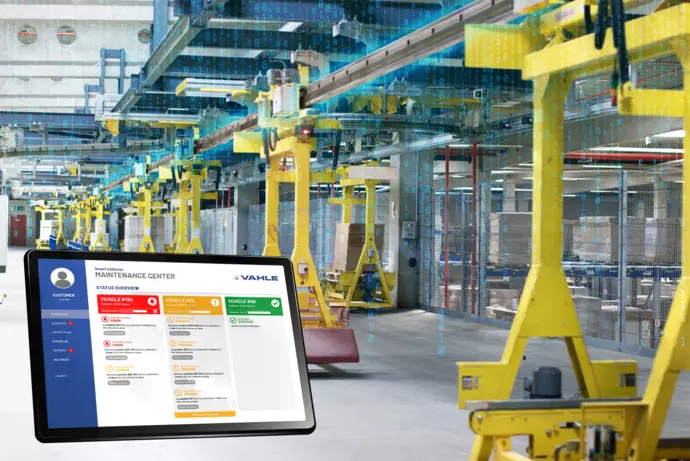

"After last year's SPS unfortunately had to be cancelled, we are all the more pleased to be able to present our product innovations such as the Smart Collector live to the public this time. With this solution, we ensure - in line with the trade fair motto 'Bringing Automation to Life' - higher plant availability and productivity for automated systems," says Achim Dries, CEO of the VAHLE Group. With the world's first intelligent current collector on the market, the Kamen-based technology pioneer is simultaneously reducing maintenance costs. "The system collects analysis data on the condition of the conductor rails as well as their components and thus prevents malfunctions at an early stage. This saves a lot of time and thus also money," says the CEO. In the meantime, VAHLE has installed the system in three pilot plants. In addition, a production line of a German automobile manufacturer is currently being equipped with the Smart Collector.

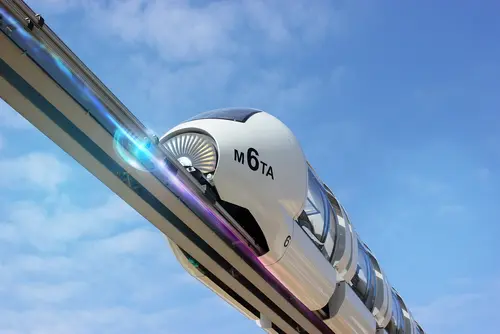

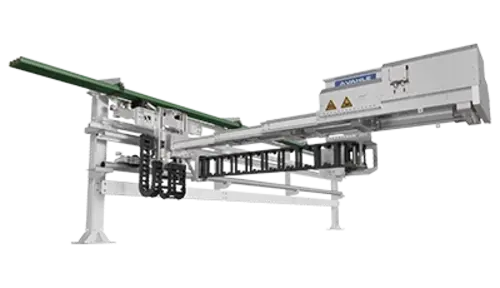

At the trade fair for smart and digital automation, VAHLE will also present a special highlight at its booth - the Rockwell Automation iTRACK. There, the ultra-compact CPS140 kHz inductive power transmission system is used, which makes it possible to continuously supply moving elements, also known as movers, with power without contact. "In addition, the complexity of the energy supply is reduced and robustness is increased," says Dries. As a result, higher process outputs can be achieved, compared to conventional energy transfer options. . The solution is therefore particularly suitable for system integrators and manufacturers of packaging machines and production lines.

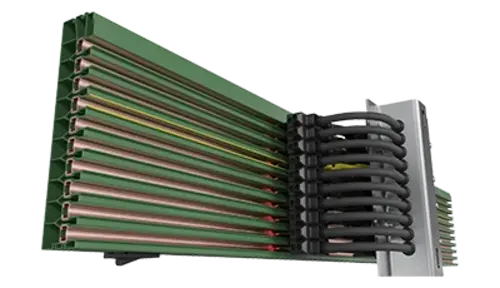

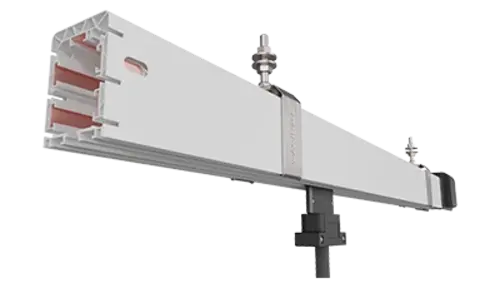

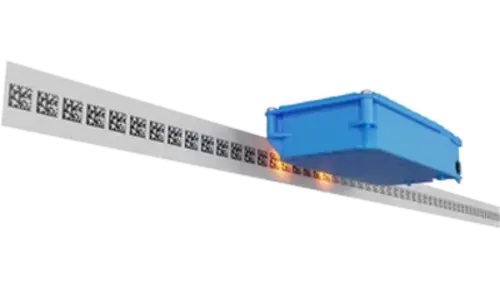

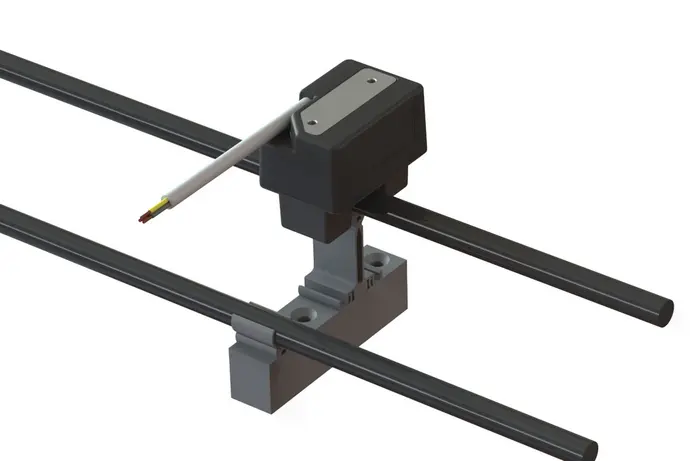

The trade fair portfolio is rounded off by classic energy transfer systems such as conductor rails or charging contacts. "Here, too, our development is not standing still. Recently, we optimized the charging contacts for improved performance and especially for outdoor use," says Dries. The VCL all-in-one conductor line is designed specifically for shuttle systems, automated small parts warehouses (AS/RS) and storage and retrieval (RGB) systems, as well as for compact transfer car and transfer trolley applications in the low and medium performance range. "In contrast to comparable solutions, the VCL stands out in particular due to its modularity, scalability and ease of assembly," emphasizes Dries. Components of the latest control generation will also be on display at the booth. VAHLE can be found in hall 4 at booth 336.