Sorter manufacturers increasingly rely on inductive energy transfer from VAHLE

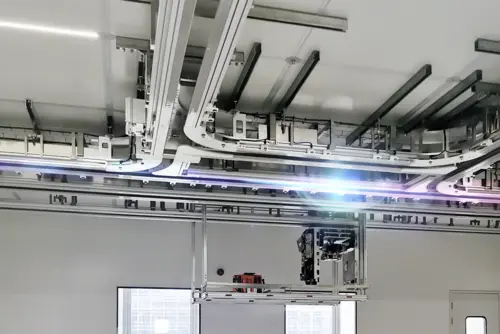

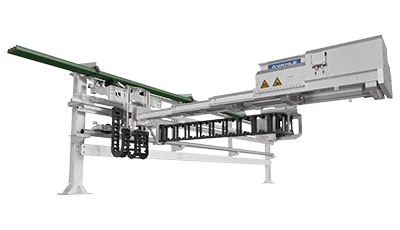

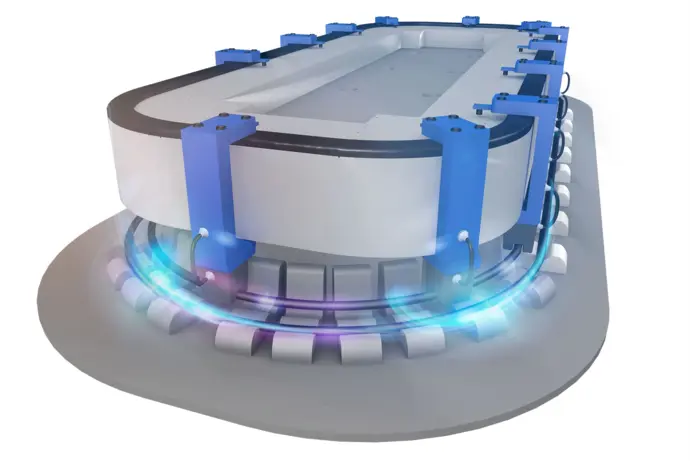

Paul Vahle GmbH & Co. KG is increasingly relying on inductive solutions for the energy supply of sorter systems, whether crossbelt or tilt-bin systems. The flexible systems are the backbone of many distribution centers and reduce the error rate in sorting and increase the efficiency of the flow of goods in incoming goods, batch picking or tour compilation in shipping. To achieve this, the hard-working helpers are in operation around the clock. In order to keep wear and maintenance costs as low as possible, the Crossbelts and Tilt Tray sorting systems are increasingly being supplied with non-contact power. Well-known manufacturers rely on the market-leading inductive solution from the Kamen-based system provider.

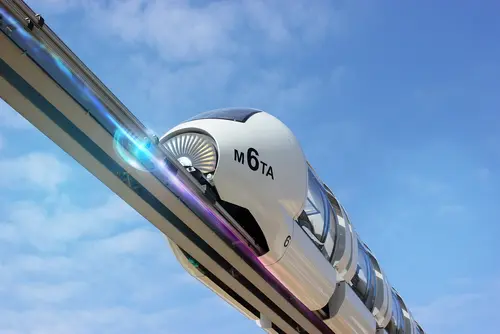

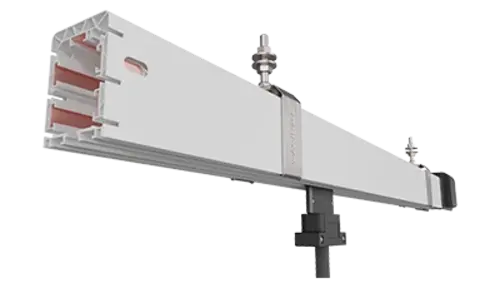

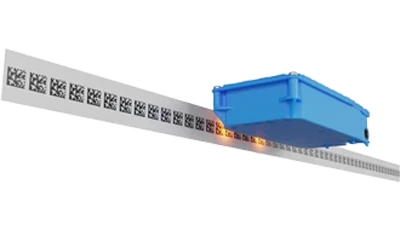

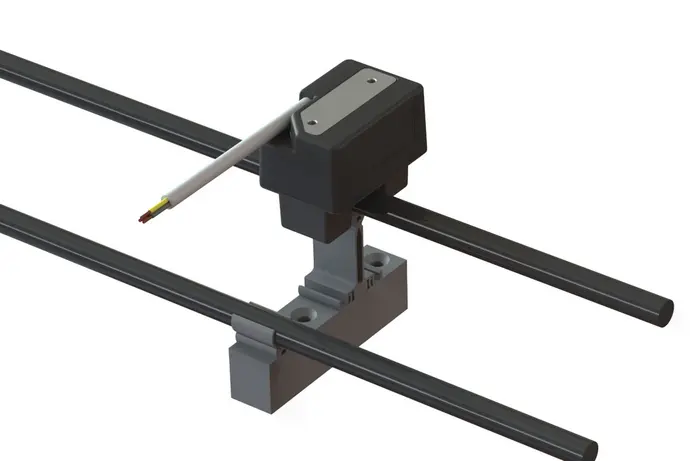

The e-commerce business is in full swing; because of the Covid-19 pandemic, more people ran their errands online last year and are likely to do so again this year. To handle the volume of shipments, many shipping centers are using automated sortation systems. "Their carriers have one or more crossbelts or even a tilt-tray function that feeds and discharges the transported goods with a high degree of accuracy or tips them into the next transport container. For this purpose, each conveyor segment has its own motor, which is then supplied with power by the compact vPOWER Pick Up," says Marc Detweiler, Head of Product Management at Paul Vahle GmbH & Co. KG.

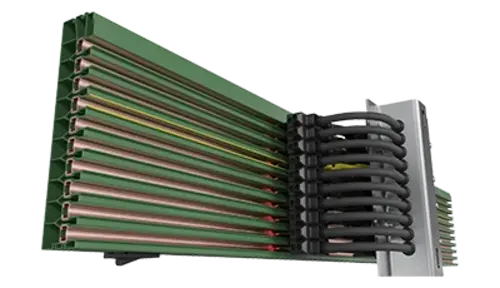

The Kamen-based system provider recommends the use of inductive technology here: "The faster and the longer a system runs, the more the carbon brushes wear out with conventional solutions," Detweiler explains. Loops several hundred meters long, speeds of up to three meters per second and almost 100 percent system availability are no longer uncommon.

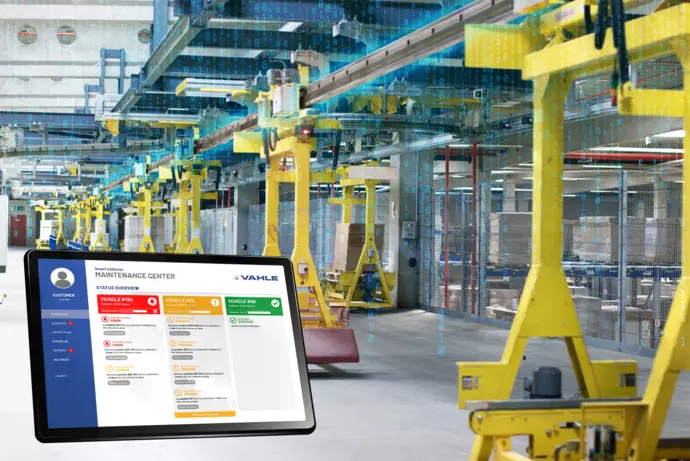

Systems with a contactless power supply for the Crossbelts or the tipping bucket system are more expensive to purchase, but have a decisive advantage: "Thanks to the inductive power supply, the vPOWER system is wear-free. This reduces the so-called Total Costs of Ownership (TCO) or total costs of operation. Thus, an acquisition usually pays for itself within a few years," says Detweiler.

Demand for crossbelt sorters remains high, especially in the eCommerce industry. "The figures from the major mail order companies show that the end of the line is still a long way off," says Detweiler, describing the outlook and adding, "Our solutions enable fast and practically continuous system operation for accurate and error-free sorting. In this way, we serve the exact needs of the industry." The expert therefore assumes that VAHLE will continue to make a decisive contribution to the growth of the market.