VAHLE conductor systems ensures reliable power supply in the new CLAAS warehouse

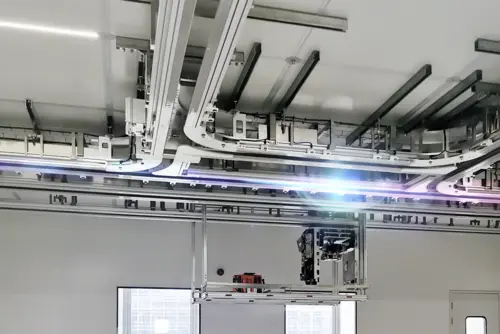

VAHLE ensures the power supply in the new spare parts warehouse of the agricultural machinery manufacturer CLAAS in Hamm-Uentrop, Westphalia. Around one kilometer of VAHLE compact conductor system was installed in the nine aisles of the automatic high-bay warehouse.

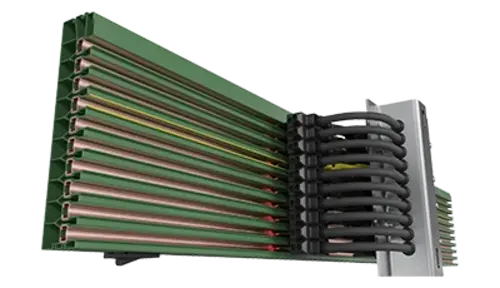

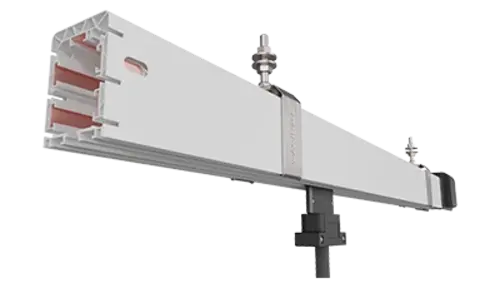

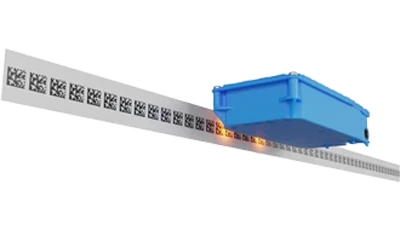

Kamen, February 27, 2020 - The conductor system type VKS 10 has been specially designed for applications where space is particularly tight. For example, it can be clipped into a support profile and thus mounted directly on the rack uprights, which eliminates the need for complex and expensive auxiliary constructions. In addition, the system is scalable and very robust.

"A reliable power supply is the be-all and end-all in automated warehouses. If the energy supply system does not function properly, malfunctions or even failures of the system can be the result. This can be expensive and should therefore be avoided," says Achim Dries, Managing Director of Paul Vahle GmbH & Co. KG. Particularly in CLAAS' new spare parts warehouse, where work is carried out in three shifts seven days a week, a reliable power supply around the clock is indispensable. To ensure this, the decision was made in favor of the compact VKS 10 conductor line, because long-life current collectors make the solution very robust and thus form the basis for continuous operation of the warehouse.

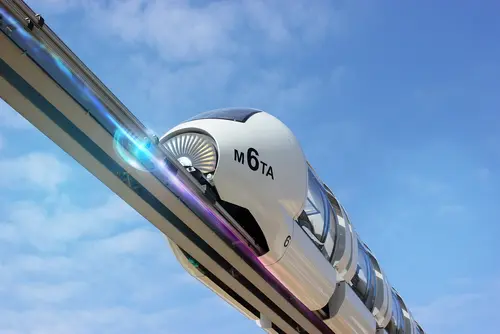

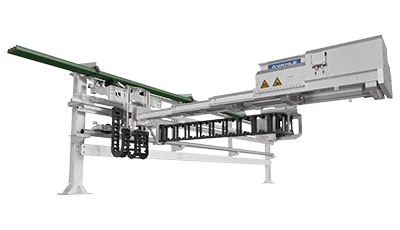

The new fully automated warehouse of CLAAS Service and Parts GmbH has been in operation since December 2019. The 11,700-square-meter facility in Hamm-Uentrop was equipped with a nine-aisle, 30-meter-high high-bay warehouse and the associated stacker cranes. The 58,000 storage locations for skeleton containers and pallets form the logistical heart of the facility. The nine DAMBACH storage and retrieval systems of the Mono type, each with two load handling devices, store and retrieve the spare parts and transfer them in pairs to the EMS vehicles, which in turn supply the picking stations.

The system thus enables particularly dynamic handling of the transport units. Another advantage of this setup is that aisles, levels and the number of stacker cranes can be easily expanded as output increases. In addition, an electric monorail conveyor (EMS) was installed as a pre-zone loop. The 350 meter long EMS is also powered by a VAHLE U10 conductor system.

The connector technology enables simple and fast conversions and extensions. "The compact conductor system is a multifunctional solution for continuous power supply, which we can configure individually according to diverse requirements and even make "Industry 4.0 ready," says Dries. The VKS10 can be optionally equipped with a positioning system and data communication without additional steel construction. Another advantage of the VKS 10 is its simple assembly - all mounting variants can be implemented here. "This is a decisive factor in the increasingly fast-growing logistics environment, where space remains limited," Dries sums up.

Responsible for the overall implementation of the new warehouse building was Unitechnik System GmbH, which CLAAS had commissioned as general contractor.