Sweet fruits are harvested with the help of VAHLE conductor systems

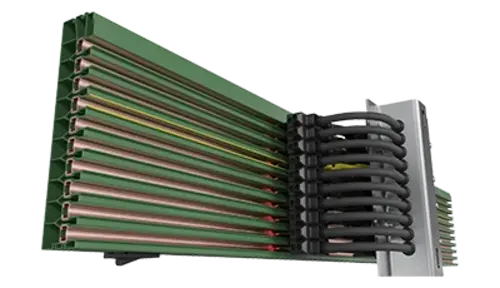

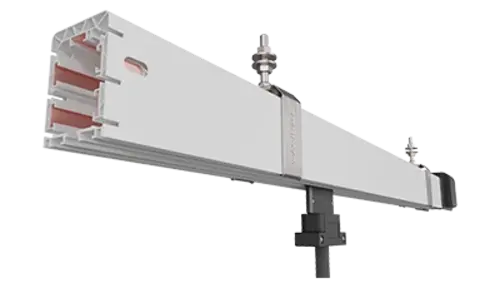

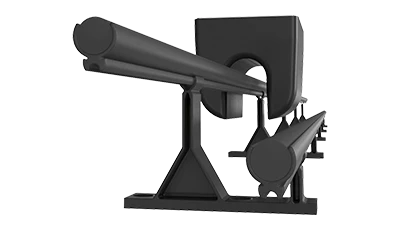

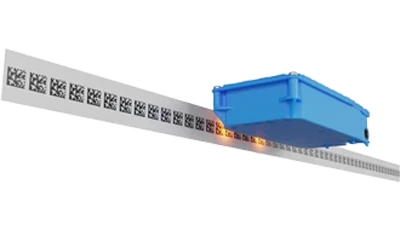

U10 conductor system

The VAHLE fact check

Industry

General Industry

year

2022

VAHLE solution

under-10s

Background

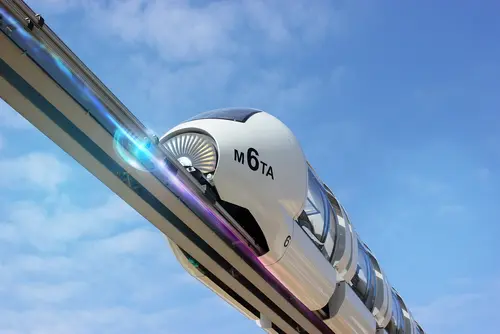

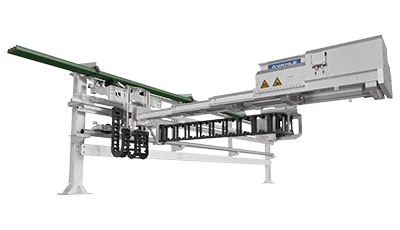

Strawberries are among the most popular fruits worldwide. The United States alone, as the second-largest strawberry producer, produces almost 1.5 million tonnes of strawberries per year. But large harvests bring with them a problem that farmers are also familiar with from the German asparagus harvest: who is going to pick the entire crop? Skilled workers are in short supply, and manual strawberry harvesting is laborious, time-consuming and expensive. The Spanish company AGROBOT (Huelva, Spain) has responded to this problem and developed a solution: a giant strawberry harvesting robot that allows a single employee to harvest the fruit of an entire field – comfortably seated and without getting their fingers dirty. The Agrobot SW 6010 model is considered the world's first fully automatic strawberry harvesting machine. This innovation promises to revolutionise strawberry harvesting and drastically reduce the amount of work required by farmers.

Challenge

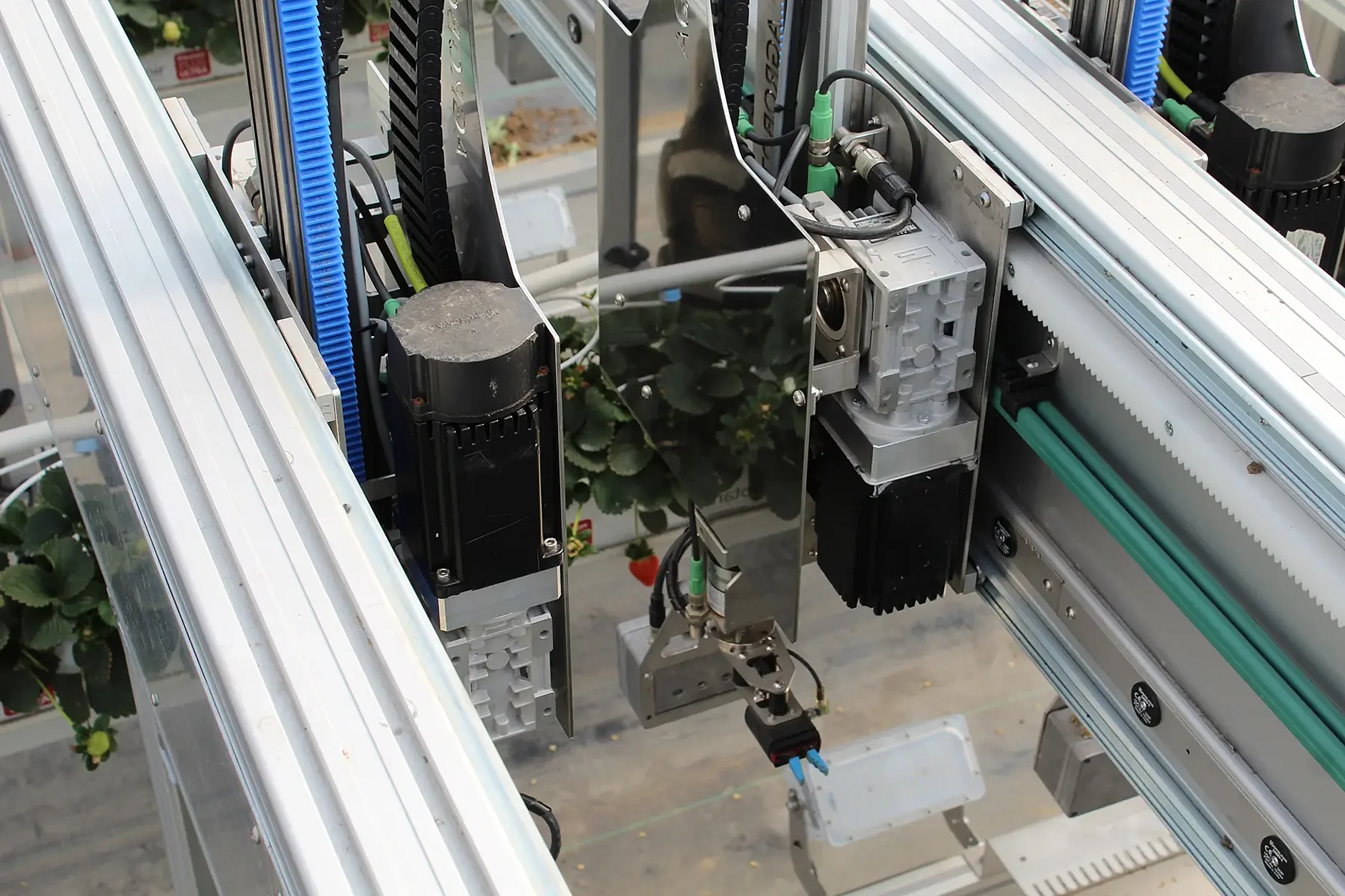

The engineers faced several challenges in developing this harvesting robot. Strawberries are extremely sensitive to pressure and do not ripen after harvesting, so they must be harvested at exactly the right stage of ripeness (red and soft). Mechanical picking must not crush or damage the fruit. In addition, the system had to be able to reliably identify ripe berries and distinguish them from unripe ones. Navigating the robot over soft, long rows of beds was also a challenge: the vehicle had to travel autonomously along the rows without damaging the plants or straying from its course. Finally, the many components – from cameras and sensors to multiple gripper arms – required a reliable power supply. Conventional cabling would have been impractical and prone to failure in the field.

Our solution

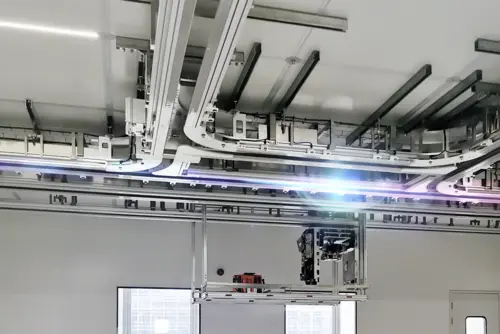

Agrobot worked closely with VAHLE to overcome these challenges. At the heart of the VAHLE solution is the proven U10 conductor system, which supplies power to the robotic picking arms of the harvesting vehicle. This innovative energy solution, otherwise used in intralogistics, ensures a continuous power supply to all grippers while the vehicle is in motion.

The results speak for themselves: tests have shown that the Agrobot can work reliably around the clock. Up to 25,000 strawberries per day can be harvested with one machine – a quantity that would otherwise require numerous harvest workers. Thanks to VAHLE, this hard-working helper never runs out of energy. This benefits agriculture in two ways: on the one hand, it alleviates the acute labour shortage during harvest time, and on the other hand, harvesting is faster and more predictable, which ensures the quality of the fruit and reduces losses.