VAHLE researches for more energy efficiency

VAHLE develops DC-powered conductor system for more energy efficiency with consortium partner. The DC Rail research project, which is funded on a federal basis, has high potential for energy savings in industry.

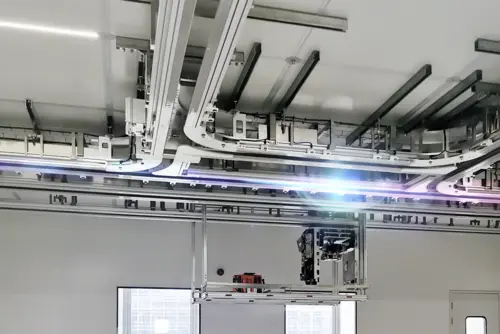

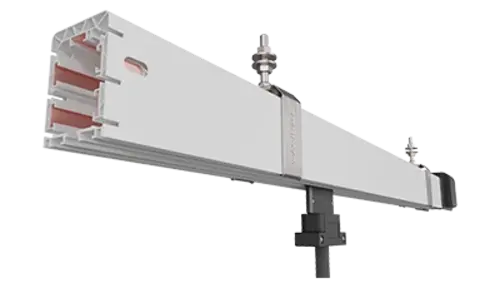

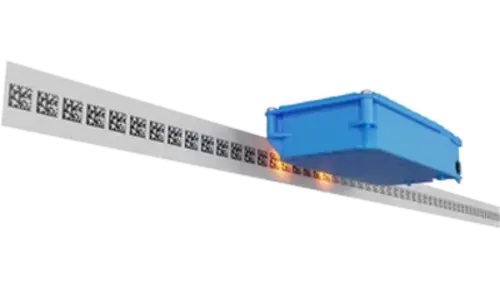

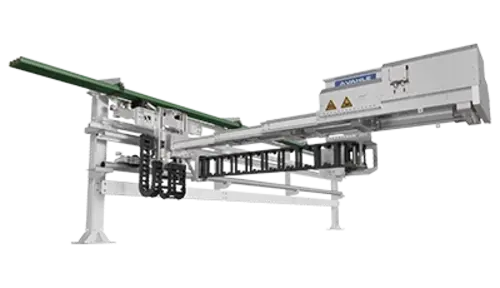

Paul Vahle GmbH & Co. KG is once again participating in a project to research the use of direct current (DC, for Direct Current) in the context of industrial applications. The focus of the project, in which the Institute for Energy Research at the Ostwestfalen-Lippe University of Applied Sciences (TH OWL) is also involved, is on so-called DC rail systems. These can be used inside and outside buildings to supply energy to mobile industrial applications such as cranes and all types of traversing and lifting equipment. Up to now, three-phase conductors (AC, for Alternating Current) have mostly been used for this purpose. However, the project partners are convinced that DC-based power supply for mobile applications offers significant efficiency and cost advantages. The aim of the project that has now been launched is to provide scientific proof of these advantages. The data material relevant for the analysis will be obtained by means of measurements on practical test systems. The project is scheduled for three years and is funded by the German Federal Ministry of Economics. In addition to VAHLE and TH OWL, the consortium includes the companies E-T-A Elektrotechnische Apparate GmbH, Lenze SE and KEBA Industrial Automation Germany GmbH.

"The topics of energy efficiency and sustainability have an increasingly greater influence on the future viability of companies. At the same time, considerable potential lies dormant in this area. We want to contribute to raising them - also in the context of fundamental work," says Achim Dries, CEO of the VAHLE Group. Among other things, this project is intended to explore the potential of direct current in industrial applications and help to make the energy supply more efficient and cost-effective.

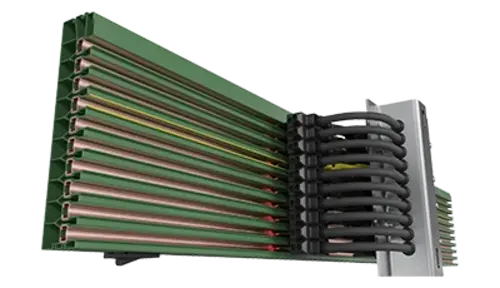

The results already obtained in the process give cause for optimism. For example, the Kamen-based systems supplier for mobile industrial applications has already been able to demonstrate in the context of another research project that the switch from AC to DC results in an increase in energy efficiency of more than ten percent. In addition, there is another advantage: the production of DC-based busbars consumes significantly less material than conventional systems. For example, the amount of copper alone, which requires a great deal of energy, is reduced by up to half.

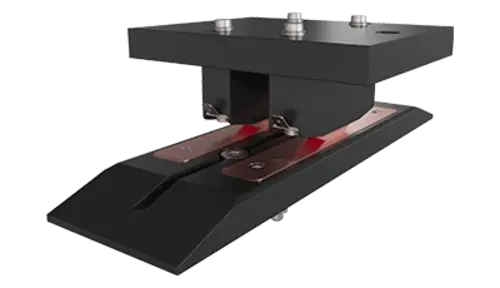

As part of the current project entitled "Highly efficient, resource-saving DC busbar systems in production and manufacturing", DC busbar for short, VAHLE and the other project partners are now devoting themselves to the system advantages resulting from the comparatively low voltage drop in DC networks. Both short and long rail systems for supplying energy to mobile industrial applications such as cranes and all types of traversing and lifting technology are being considered. Further emphasis is placed on the integration of regulated storage systems of medium and high capacity. Of particular interest are the effects of the storage units on voltage drop compensation and peak load leveling.

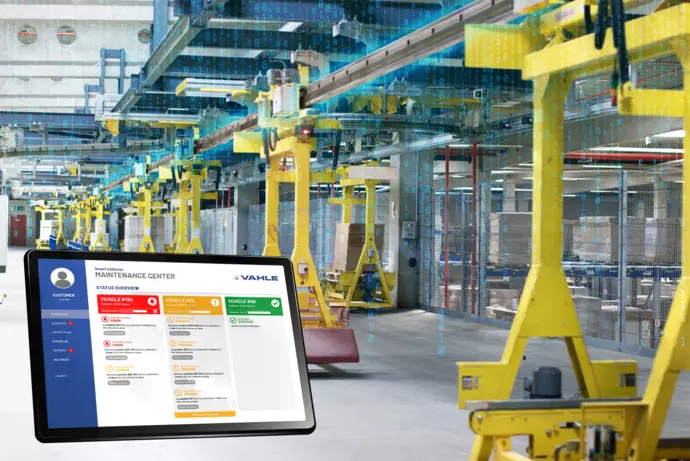

The measurements required in this context will be carried out on test setups installed on VAHLE's premises in Kamen as well as at TH OWL. The systems consisting of feeder, inverter and DC/DC converter technology for industrial DC networks are specially designed for use in busbar systems. VAHLE project manager Stefan Bürmann: "In the course of this, we will also use a DC protection and switching technology that is completely new for busbar systems, whose sensor technology is already designed for so-called condition monitoring and predictive maintenance by means of AI."

VAHLE also wants to demonstrate by means of various tests that DC systems also have a positive impact beyond their primary effects and help to save energy and resources along the entire value chain.

Another essential aspect of the project is the optimization of the inverter technology. "DC feeding eliminates the need for a rectifier and the DC link capacitor can be designed smaller," Bürmann explains.

The project, which is funded by the German Federal Ministry of Economics and Climate Protection, is being supervised by the Jülich Research Center and is scheduled to run for three years. However, Stefan Bürmann is already convinced: "The change from the old AC to the new DC technology is tantamount to a paradigm shift - and is unquestionably one of the industry's greatest levers for significantly reducing energy consumption."

Further information about VAHLE at: www.vahle.de