VAHLE presents innovations for industrial automation at SPS

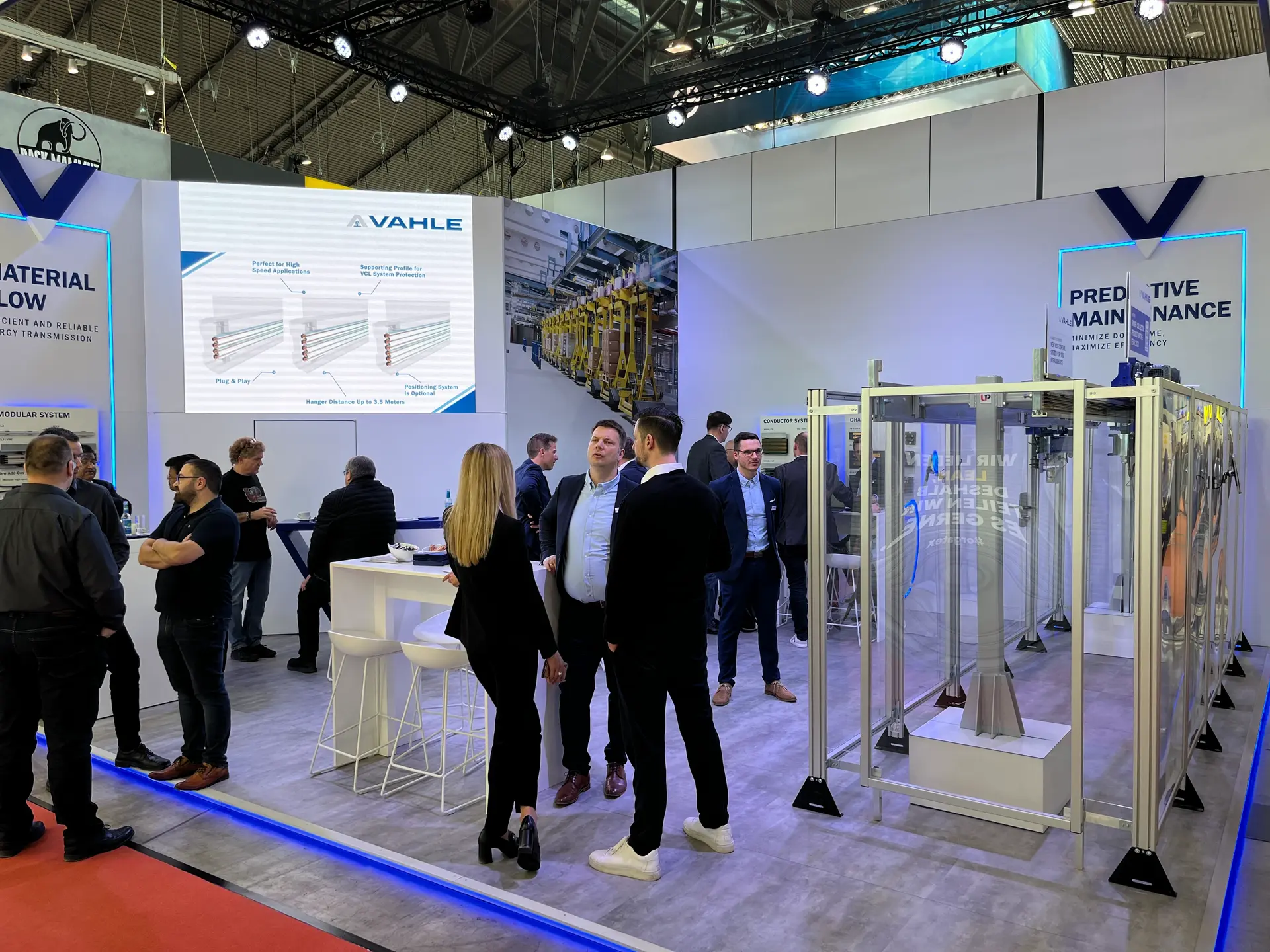

Under the motto "Making your application future-proof", Paul Vahle GmbH & Co. KG will be presenting innovative solutions for industrial automation at SPS 2024 in Nuremberg. Highlights include the optimized vDRIVE control system and contactless energy transmission. Visit VAHLE in hall 4, booth 336.

Paul Vahle GmbH & Co KG will be presenting various innovations for industrial automation at this year's SPS (Smart Production Solutions) from November 12 to 14 in Nuremberg. Under the motto "Making your application future-proof", the system provider for intelligent automation solutions and mobile industrial applications will be demonstrating how existing and new systems can be designed to be efficient and future-proof. The focus will be on upgrades to the vDRIVE control system for mobile conveyor units, among other things. Another highlight at the trade fair is the product portfolio for contactless energy transmission. VAHLE will be presenting these and other products in Hall 4 at Stand 336.

"Every year, SPS is the trade fair highlight for us in the field of automation. This is where we meet the leading minds in the industry and present our latest innovations," says Andre Adolph, Business Unit Manager Automotive at VAHLE, adding: "With our new technologies and upgrades, we want to provide our customers with tools to make their applications future-proof."

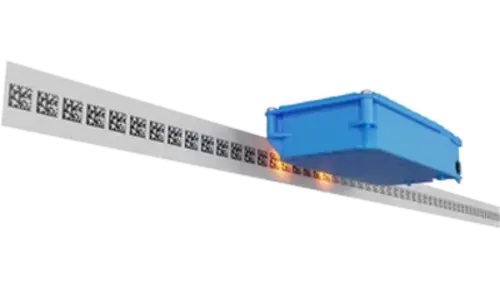

Interested visitors to the VAHLE stand will be able to find out about the latest upgrades to the VCS1 and VSCX control systems from the VAHLE vDRIVE portfolio. Both solutions now have a rail bus extension that enables more intelligent process control. "The new functions make it easier for both new systems and retrofit applications to make systems more flexible and efficient," explains Adolph.

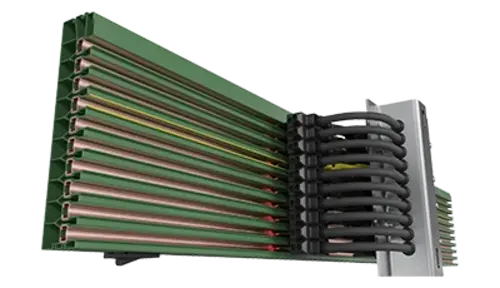

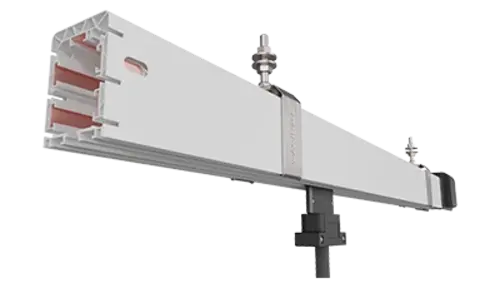

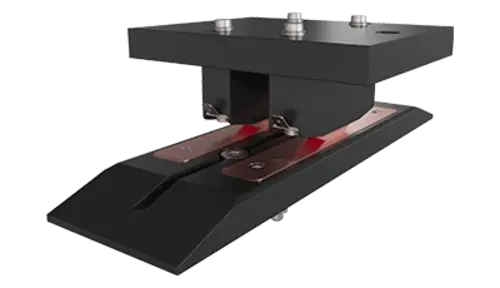

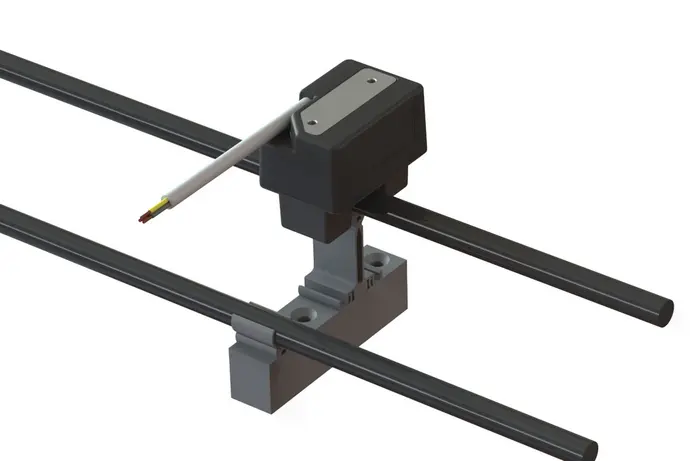

Particular attention is also being paid to the CPS® (Contactless Power Supply) system. VAHLE is one of the few companies in the world that can boast the internationally recognized SEMI S2/S22 certification for this. This confirms compliance with the strict safety and energy efficiency requirements for machines and systems in the semiconductor industry. With the CPS140 products, VAHLE is thus consolidating its leading position in this sector. "The technology enables maintenance-free operation with high efficiency, which ensures maximum uptime and minimum downtime," Adolph emphasizes the advantages.

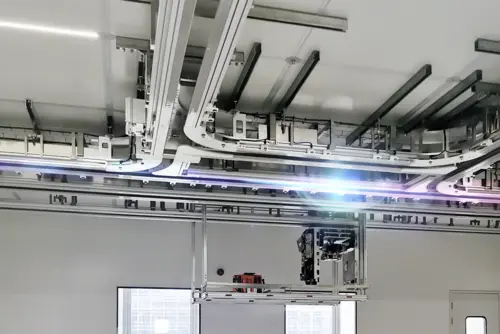

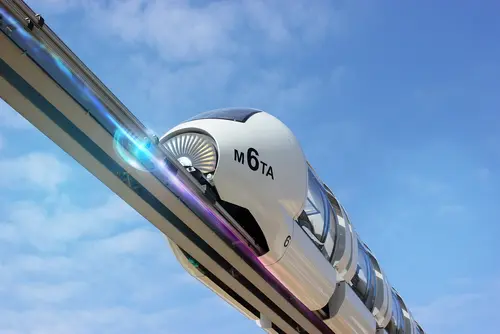

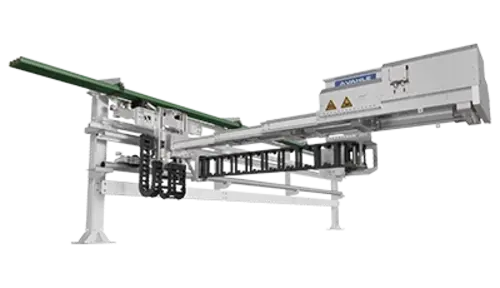

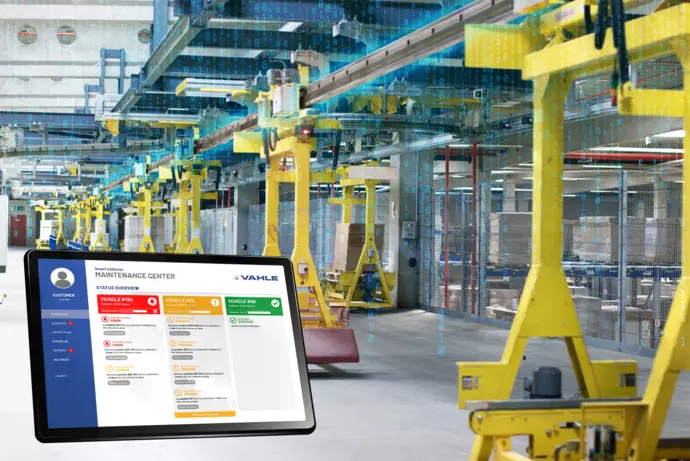

VAHLE will also be exhibiting a fully automated electrified monorail system at its stand, which is equipped with the latest tools and the Smart Collector. This enables automated and rapid monitoring of the conductor rails and associated systems without interrupting ongoing operations. "This innovation is a decisive contribution to preventive maintenance in order to avoid unplanned downtime," says Adolph.

This year, VAHLE is offering visitors the opportunity to experience the solutions up close and see the benefits for themselves. For detailed consultations, interested parties can arrange a personal appointment on site with the VAHLE experts to ensure that their plants are set up for the future. VAHLE can be found in Hall 4 at Stand 336.