VAHLE presents new product innovations at LogiMAT

The intralogistics highlight in March 2024: LogiMAT in Stuttgart. VAHLE presented the latest products and solutions there and is now presenting them in the new innovation magazine VAHLE Visions.

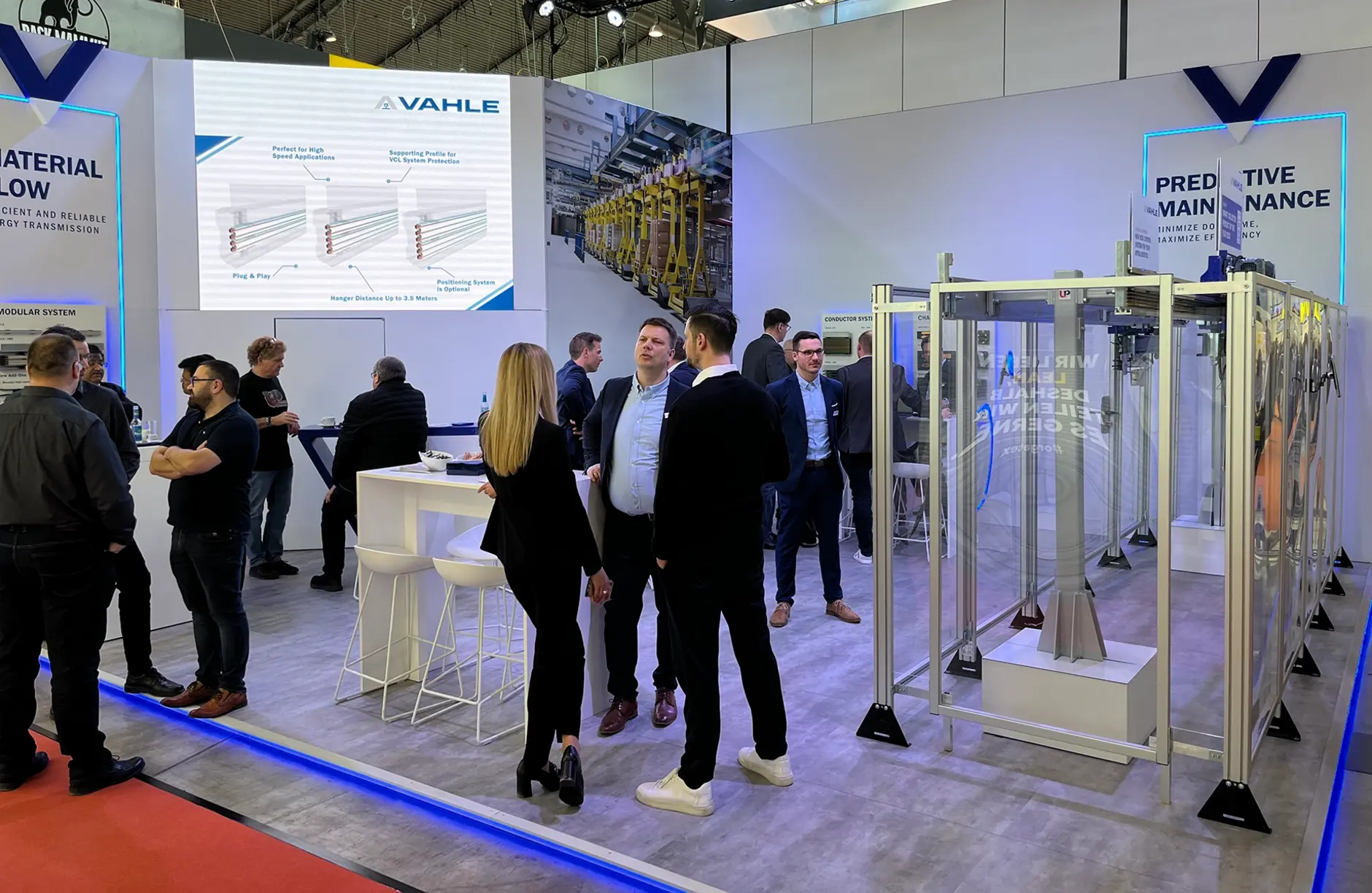

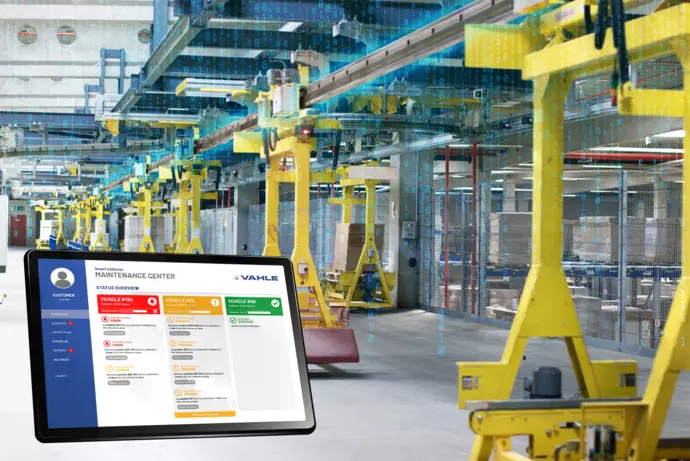

LogiMAT 2024 in Stuttgart is an annual highlight in the trade fair calendar for Paul Vahle GmbH & Co. KG and was once again a real fixture in the presentation of innovative solutions for intralogistics this year. From March 19 to 21, 2024, the company presented its latest products in Hall 1, Stand C31, which this year housed the highlights in a new design. The focus was on the predictive maintenance of intralogistics processes and conveyor systems, which is made possible by the Smart Collector. The unique predictive maintenance tool detects anomalies in systems at an early stage in order to minimize downtimes and increase productivity.

Once again this year, the most important intralogistics trade fair in Stuttgart was a huge crowd puller. In addition to the Smart Collector, many other new products and innovative solutions were presented, which are described in detail exclusively in the current issue of VAHLE Visions. There you will find a comprehensive overview of the latest solutions from the Kamen-based system provider.

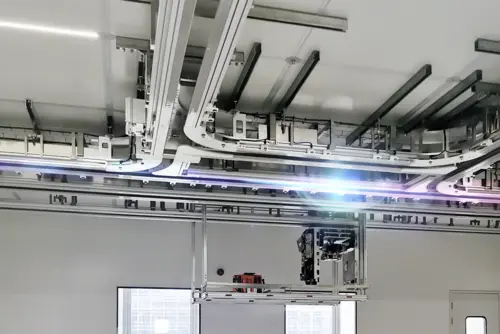

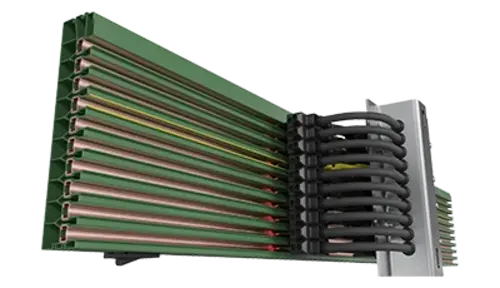

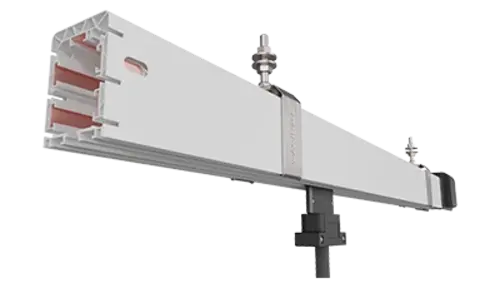

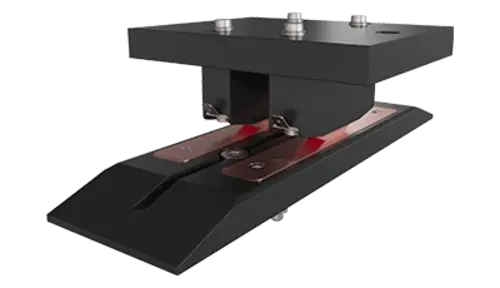

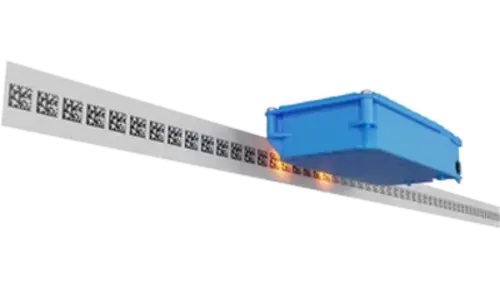

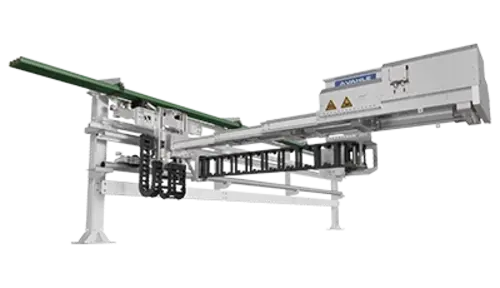

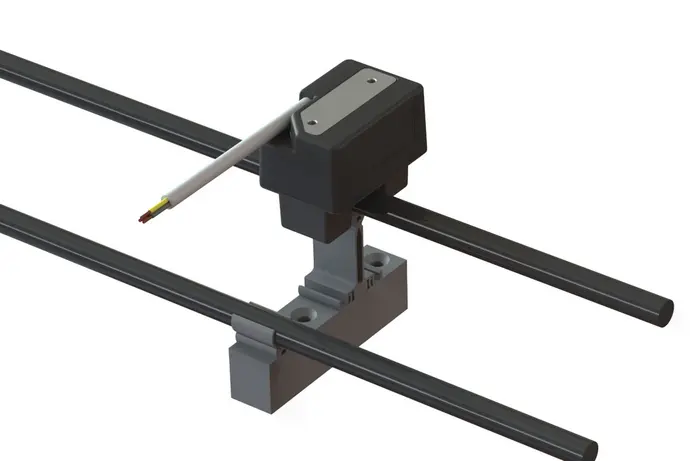

Among other things, the latest add-ons and additions for the All-In-One conductor rail VCL were presented, which guarantee a safe flow of goods, especially in the area of shuttle applications. An innovative modular hopper now makes the VCL suitable for fast level and aisle changes at a speed of 4 meters per second. A new cleaning module ensures smooth and, above all, safe shuttle operation, free from contamination problems. A condition monitoring upgrade is also now available for this conductor rail, which significantly improves system availability by analyzing carbon brush wear and indicating a replacement in the event of a reserve status.

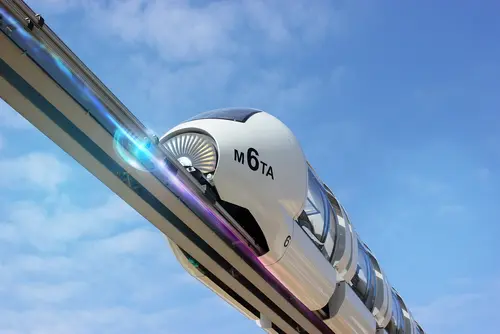

In the non-contact energy transmission segment, various upgrades and innovations are available in the inductive portfolio. A space-saving new power supply makes the use of control cabinet solutions obsolete. In addition, the CPS 140 technology has been certified for use in the overhead hoist transport segment and therefore meets the highest standards in the OHT application area.

The VAHLE control portfolio is rounded off by the introduction of the new VSCX rail bus intralogistics controller. Another highlight is the new PowerNet, a simple addition for communication via conductor rail, which conveniently modifies the crane conductor rail into an automation system.

VAHLE invites all interested parties and customers to immerse themselves in the new innovation magazine VAHLE Visions.

Click here to register for the newsletter and download VAHLE Visions: VAHLE Visions