Extreme conditions in deep-freeze storage - a challenge for energy transfer systems

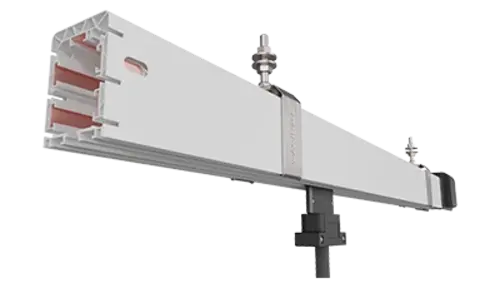

VKS10

The VAHLE fact check

Industry

Intralogistics

Extreme conditions

up to -30°C

Length

~288 m (VKS10)

The challenge

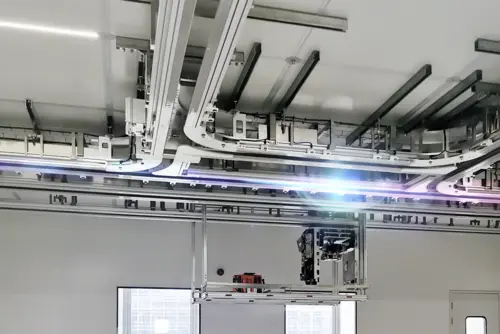

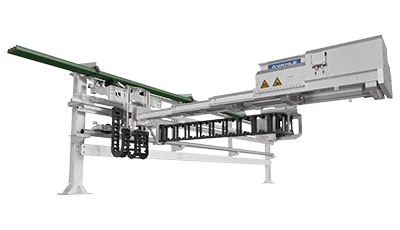

An international retailer was experiencing significant problems with its automated storage and retrieval system in a deep-freeze warehouse. The previous conductor rail system used by a competitor was unable to cope with the extreme temperatures - resulting in material fatigue, system failures and expensive downtime.

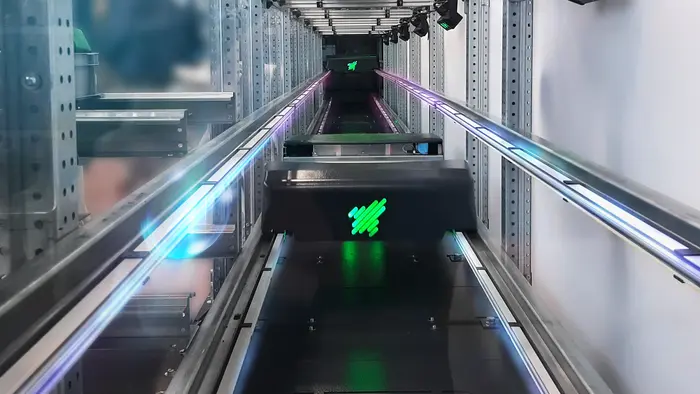

Deep-freeze bearings are particularly demanding: temperatures as low as -30 °C and extremely low humidity with a low oxygen content. This leads to increased wear and a shortened service life of the components.

Our solution

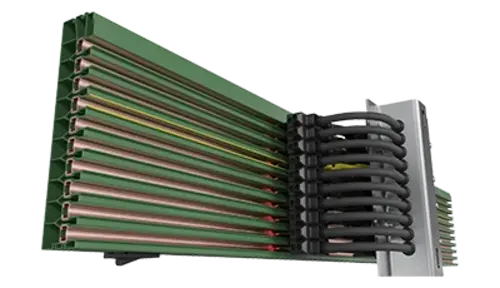

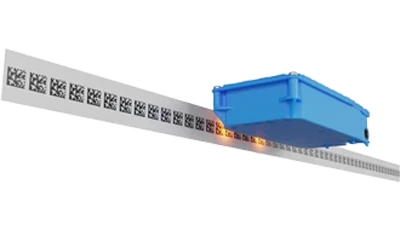

VAHLE supplied the VKS10 compact conductor rail in modular 4-metre segments - specially developed for use in deep-freeze environments.

- Cold-resistant materials

- Reliable energy transfer at sub-zero temperatures

- Special carbon brushes for reduced wear on the conductor rail system

- Easy maintenance and replacement

- Higher availability and better performance

Added value for the customer

The customer benefits from reliable energy transmission via the VKS10 conductor rails with significantly fewer failures. The components specially designed for deep-freeze areas ensure a long service life for the current collectors and conductor rails - and therefore low maintenance and follow-up costs. The maintenance team can concentrate on other priorities.

Deep-freeze areas require intelligent solutions - and VAHLE supplies them.