VAHLE presents developments for eco-friendly port concepts at TOC Europe in Rotterdam

VAHLE presents at TOC Europe: Focus on efficient and sustainable container handling.

Paul Vahle GmbH & Co. will showcase innovative advancements for sustainable maritime logistics chains at this year's TOC Europe in Rotterdam, Netherlands, from June 11 to 13. The system provider for mobile industrial applications will spotlight various automation and power transmission solutions aimed at enhancing energy efficiency and reducing CO2 emissions at port terminals. A concrete example is the application of real-time data communication, which will enable wireless container handling in the future and significantly contribute to reducing resource demand.

“Ports serve not only as hubs of global trade but also as centers for innovation and sustainability. The future of container handling is characterized by zero emissions and port automation. With our pioneering solutions, we support this transformation towards environmentally friendly and highly automated port facilities,” says Jaroslaw Warzecha, Director of the Port Business Unit at VAHLE Group. The company from Kamen has always played a leading role in developing sustainable technologies in the maritime industry.

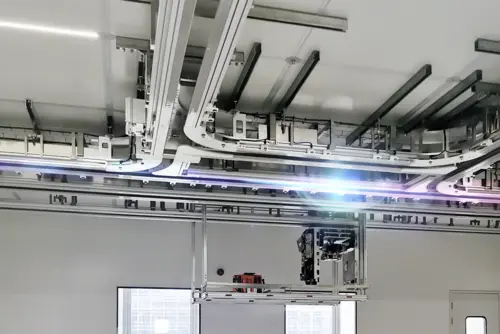

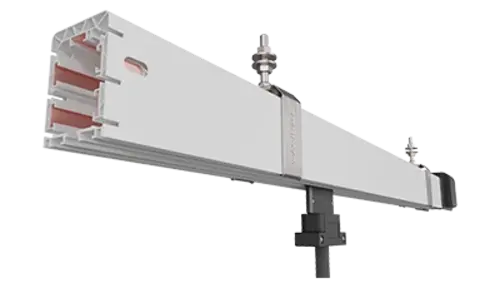

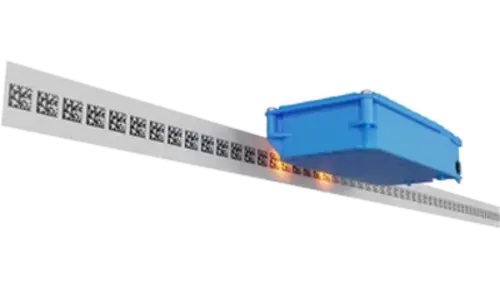

The focus at the booth will be particularly on the electrification of port terminals. In this context, VAHLE recently updated its data transmission system, vCOM. By implementing the secure SMGX communication standard (Slotted Microwave Guide Extreme), a powerful data rate of up to one gigabit is achieved. “This ensures uninterrupted communication, which increases safety and enables fully automated and remote-controlled port operations,” explains Warzecha. Additionally, a suitable retrofit solution for existing crane systems is planned to allow for immediate system optimization.

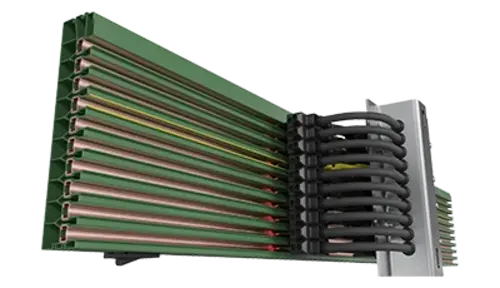

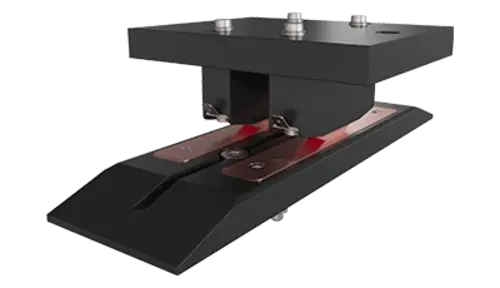

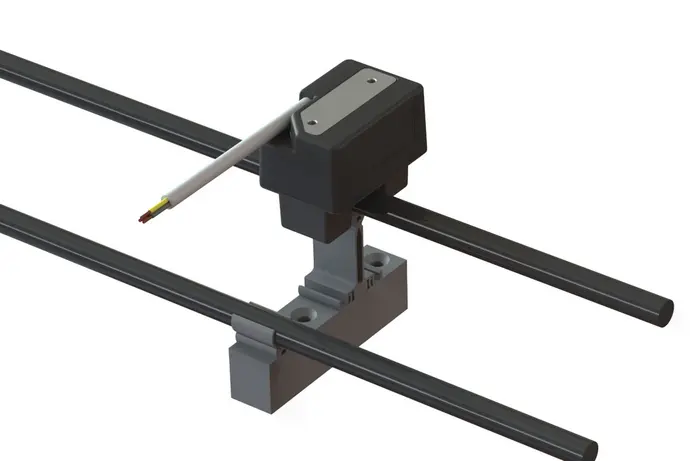

By utilizing the wireless Slotted Microwave Guide Extreme (SMGX) technology in conjunction with Wi-Fi 6, simultaneous transmission of control data and multimedia data is ensured, enabling wireless container handling. “With this solution, port operators achieve higher efficiency and productivity without compromising environmental compatibility,” says Warzecha. The integration of this system, which combines SMGX data and power transmission via a power rail, eliminates the need for wired applications such as festoon systems or energy chains on the STS crane in the future. This not only leads to a reduction in maintenance and service costs but also to significant weight savings. This offers a direct cost advantage for crane manufacturers in designing new cranes, especially under harsh and extreme weather conditions. Furthermore, the elimination of the festoon system on the STS crane leads to increased stacking capacity on the container ship.

Integrating Profibus technology and HTL encoder transmission in real time renders costly and maintenance-intensive festoon systems obsolete, even for existing cranes. “From weight savings to remote control from the terminal tower, our solutions enable efficient, sustainable, and future-proof automation of container handling in ports,” explains Warzecha.

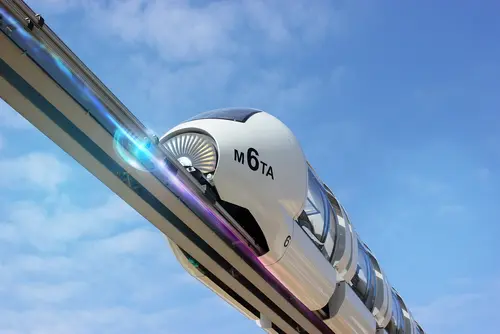

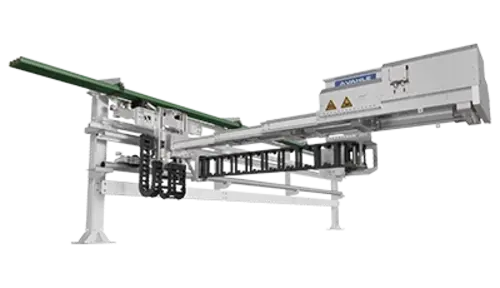

VAHLE will also present the latest generation of its solution for rubber-tired gantry cranes, abbreviated as RTG (Rubber Tyred Gantry Cranes) – Trimotion Compact, at the exhibition. This system enables fully electric and automated remote handling of eRTG cranes in the terminal alleys.

At TOC Europe, one of the world's largest trade fairs for port, shipping, and terminal technology, VAHLE will exhibit at Stand E20. “Our vision is that of a fully automated Green Port. Everyone is invited to visit our booth and see our solutions on-site. Our global team from the APAC, EMEA, & Americas regions will be present and looks forward to your visit,” says Warzecha.

For more information about VAHLE visit: https://www.vahle.de