Start of apprenticeship: VAHLE welcomes 15 junior employees

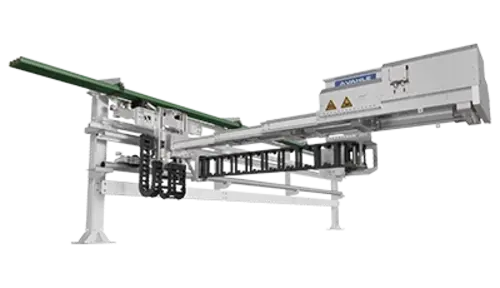

With 15 new trainees in ten professions, including the new fields of electronics for industrial engineering and machining mechanics, Paul Vahle GmbH & Co. KG is starting the 2024 apprenticeship year.

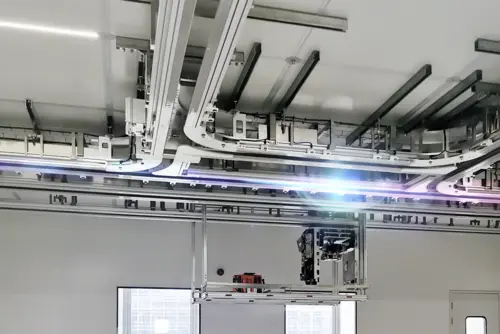

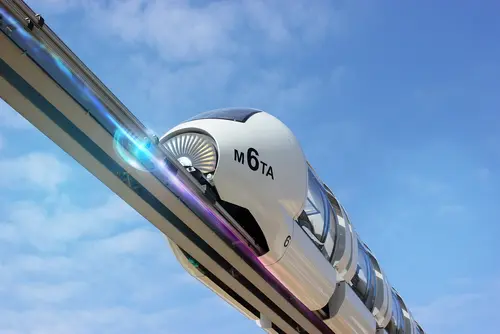

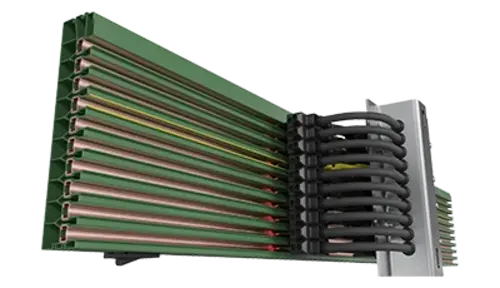

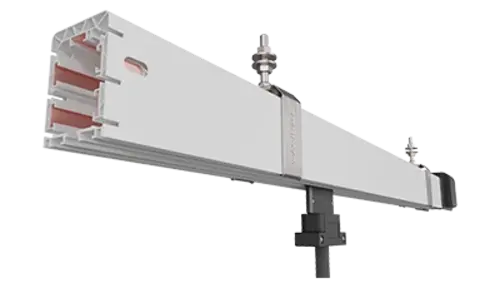

Paul Vahle GmbH & Co KG welcomes 15 new trainees in ten different apprenticeships. Due to the increased need within the company and the growing demand among career starters, the leading system provider for mobile industrial applications is offering apprenticeships in the professions of electronics for industrial engineering, industrial electronics for industrial engineering and machining mechanics for the first time. The Kamen-based company has been specifically promoting young talent for years and supporting them right from the start. This year, too, the new trainees can look forward to four exciting and varied induction days.

"Training at VAHLE lays the foundation for a successful career for new specialists. That's why we attach great importance to providing them with advice and support right from the start," says Kathrina Adelsberger, Head of Training at VAHLE. A varied welcome program awaits the trainees in their first few days. "In addition to an introduction to our company, the industry and our products, as well as safety instructions and equipment with the necessary technology, the focus of the induction week is also on getting to know the newcomers and their colleagues personally," says Adelsberger.

The week kicked off today with an atmosphere barometer to get to know each other and the trainees were welcomed by CHRO Sarah Dunker and the trainers. A wide range of training and instruction sessions are on the agenda for the coming days. Even after the orientation week, the trainees are not left to their own devices. On August 20, the annual trainee excursion will take place as a highlight, where all the starting years can network with each other during an eventful day.

VAHLE, the largest employer in Kamen, strives to provide the best possible learning conditions for its trainees. In addition to comprehensive support, this also includes the provision of modern technology. "It is now standard for our trainees to receive their own laptops. In order to take a further step towards digitalization, this year the trainees are using the digital report booklet, which was previously only available in printed form or as a Word document," says Adelsberger.

With the 15 newcomers, the family business is currently training a total of 43 skilled workers. The new intake includes an industrial clerk, a production mechanic, two metal technology specialists (assembly technology), four industrial clerks with an additional EU qualification, two warehouse specialists, an industrial electrician for devices and systems, an electronics technician for industrial engineering, an industrial electrician for industrial engineering, a cutting machine operator and a technical product designer (machine and system design).

August is not only a milestone for the new training year: on August 28, the congratulatory event for the graduating class will take place, at which the newly trained specialists will be honored.

The Kamen-based company is delighted with the successful start of the new trainees. VAHLE is already looking for further committed trainees in order to continue its long-term promotion of young talent next year.

Further information about training at VAHLE can be found at: https://www.vahle.de/karriere/ausbildung-bei-vahle